Lithium battery tape

Made with PP/PET/PI film and electrolyte-resistant acrylic adhesive. Available in 0.016-0.05mm thicknesses. Provides insulation, strong adhesion, and flame resistance for lithium-ion battery protection.

High-temperature lithium battery tapes are made from insulating materials (PP, PET, or PI films) coated with a lithium battery electrolyte-resistant acrylic adhesive. Available in thicknesses of 0.016mm, 0.020mm, 0.03mm, 0.035mm, 0.04mm, and 0.05mm, they are specifically designed for insulating and securing lithium-ion battery cells and other components. They offer strong electrolyte resistance, high adhesion, excellent conformability, and are environmentally friendly and flame-retardant.

Production Process Flow

From raw materials to finished product, every step is rigorously controlled to ensure consistent and reliable performance.

- Base Material: High-temp films like PI, PET, or PTFE (10–50μm thick).

- Adhesive: Silicone or acrylic-based, with heat-resistant additives (e.g., silane coupling agents).

- Accessories: Release paper (protects adhesive), solvents (toluene/MEK for dilution).

- Surface Cleaning: Plasma or chemical treatment to remove impurities and improve adhesion.

- Primer Coating (optional): Enhances bonding between base and adhesive.

- Methods:

Transfer Coating: Adhesive applied to release paper first, then transferred to base.

Direct Coating: Adhesive applied directly to base (requires precise thickness control). - Drying: Oven-dried at 80–150°C to evaporate solvents.

- Release Paper Lamination: Protects adhesive layer.

- High-Temp Curing: Some adhesives require curing at 120–180°C for enhanced heat resistance.

- Slitting: Cut into custom widths (e.g., 5mm, 10mm).

- Rewinding: Rolled to standard lengths (e.g., 50m, 100m/roll).

- Die-Cutting (optional): Shapes like circles or squares.

- Packaging: Dust/moisture-proof (cardboard or anti-static bags).

- Heat Resistance Test: 200°C for 1 hour (no warping/delamination).

- Adhesion Test: 180° peel strength (≥1.5N/cm).

- Insulation Test: Withstands ≥5kV.

- Visual Inspection: No bubbles, impurities, or scratches.

Lithium battery tape Series Specification Sheet

| Name | ltem No.Model | Material | Colour | Adhesive | standard size | Tack | Adhesion Strength | Tensile Resistance | Exten- sibility | Voltagewithstand | Temperature tolerance | ||

| thick/mm | wide/mm | long/m | N | N/25mm | N/25mm | % | ℃ | ||||||

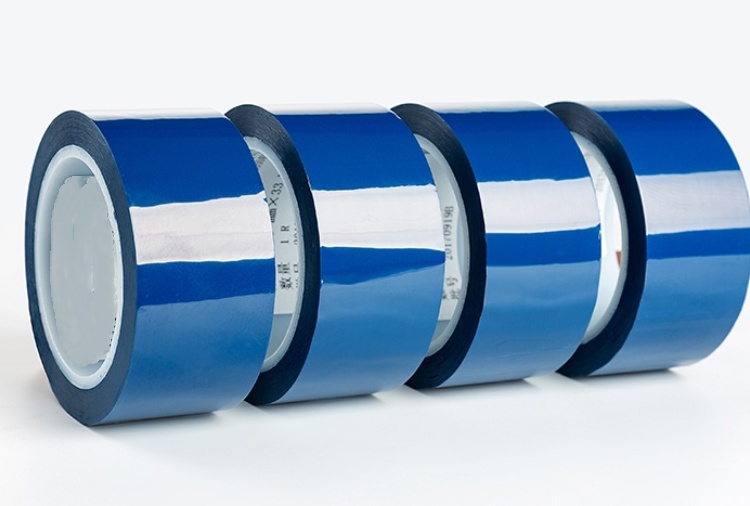

| Power battery blue film tape | PT11A | PET | blue | acrylic acid | 0.11 | 950 | 50/100 | 3.5↑ | 10↑ | 150↑ | 45 | 5kv | 120 |

| Power battery blue film tape | PT08A | PET | blue | acrylic acid | 0.08 | 950 | 50/100 | 4↑ | 10↑ | 120↑ | 40 | 5kv | 120 |

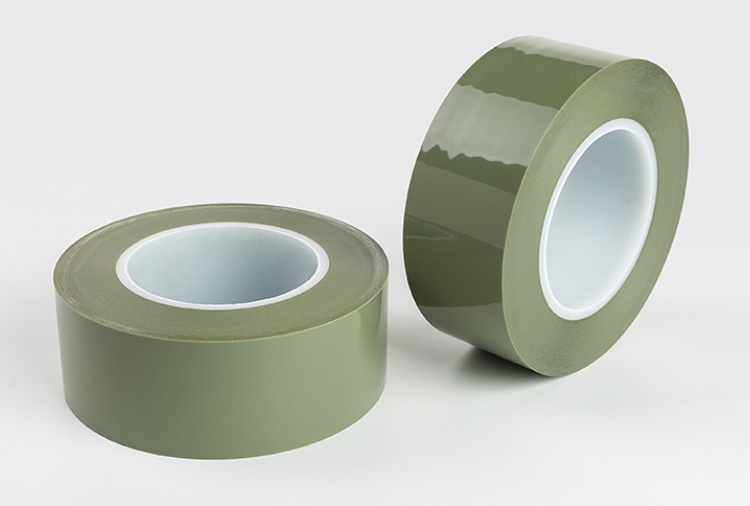

| Lithium battery termination tape | PP03G | BOPP | green | Electrolyte Resistant PSA | 0.035 | 500 | 100/200 | 0.5↑ | 3↑ | 60↑ | 80 | 3kv | 130 |

| Lithium battery termination tape | PP05G | BOPP | green | Electrolyte Resistant PSA | 0.05 | 500 | 100/200 | 3↑ | 7↑ | 60↑ | 80 | 3kv | 130 |

| Lithium battery termination tape | PP02G | PET | green | Electrolyte Resistant PSA | 0.016 | 500 | 100/200 | 3↑ | 7↑ | 60↑ | 80 | 3kv | 130 |

| Ni-MH battery tape | PP09A | BOPP | yellow | rubber | 0.085 | 580 | 100/200 | 3↑ | 5↑ | 100↑ | 50 | 4kv | 80 |

| Lithium battery tab tape | KA03D | PI | golden yellow | rubber | 0.035 | 500 | 100/400 | 3↑ | 2↑ | 90↑ | 50 | 3kv | 130 |

| Lithium battery tab tape | KA04D | PI | golden yellow | rubber | 0.045 | 500 | 100/200 | 1↑ | 2↑ | 110↑ | 30 | 3kv | 130 |

| Lithium battery tab tape | KA06D | PI | golden yellow | rubber | 0.055 | 500 | 100/400 | 3↑ | 7↑ | 130↑ | 50 | 5kv | 130 |

Technology Showdown: PET Tape vs. PI Tape

The choice of base material is critical for lithium battery tapes. While both PET and PI films provide excellent insulation, their differences in thermal performance, mechanical properties, and cost have a profound impact on application suitability.

Functions, Uses, and Applications

Lithium battery tape is an essential high-performance material in battery manufacturing. Its core function is to provide insulation, fixing, and protection throughout the complex cell and pack assembly workflow.

Quality Standards & Certifications

Jiujiang Leadcomp Co., Ltd. is committed to delivering the highest quality products, a promise backed by strict internal standards and authoritative third-party certifications.