Beyond The Bond How High-Temperature Tapes Master Thermal Management In Electronics

As electronic devices become smaller, faster, and more powerful, they generate an increasing amount of heat, creating a significant challenge for designers and engineers. This rise in thermal stress can lead to performance degradation, premature component failure, and a shortened product lifespan. Specialized high-temperature adhesive tapes are no longer just simple fasteners; they have evolved into critical, functional components of a sophisticated thermal management system. By effectively dissipating heat, providing essential electrical insulation, and securing delicate components, these advanced tapes ensure the reliability, durability, and safety of modern electronics. Explore how these innovative materials are safeguarding the future of technology. High-temperature tapes play a key role.

The Invisible Threat of Thermal Stress

The operation of all electronic devices involves the movement of electrical current, which inevitably generates heat. This thermal energy, if left unmanaged, can cause a chain reaction of problems. As temperatures rise, the properties of materials can change, leading to increased electrical resistance and a reduction in mechanical strength. This thermal stress can cause connections between components and packages to weaken and break, ultimately leading to system failure and a poor user experience. Modern devices, from smartphones to industrial automation systems, face an acute challenge: they are required to dissipate a high density of heat from a limited space, making effective thermal management a non-negotiable part of the design process.

The Evolving Role of Adhesive Tapes

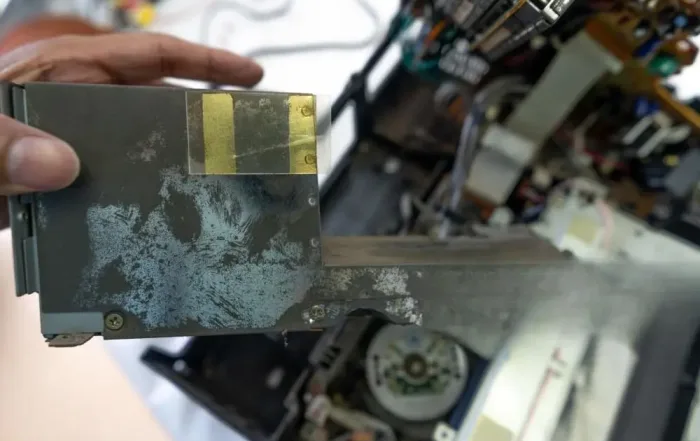

High-temperature adhesive tapes are specifically engineered to meet the stringent demands of electronics manufacturing, where processes like soldering and reflow soldering can subject components to temperatures reaching several hundred degrees Celsius. These tapes are designed to maintain their adhesive and structural integrity under such extreme conditions. Their role goes far beyond simple bonding; they act as a vital line of defense, providing insulation and protection for sensitive electronic components. By preventing heat damage, reducing thermal stress, and helping to maintain optimal operating temperatures, these tapes are an essential tool for ensuring the long-term reliability and safety of electronic devices.

How Tapes Dissipate Heat And Protect Components

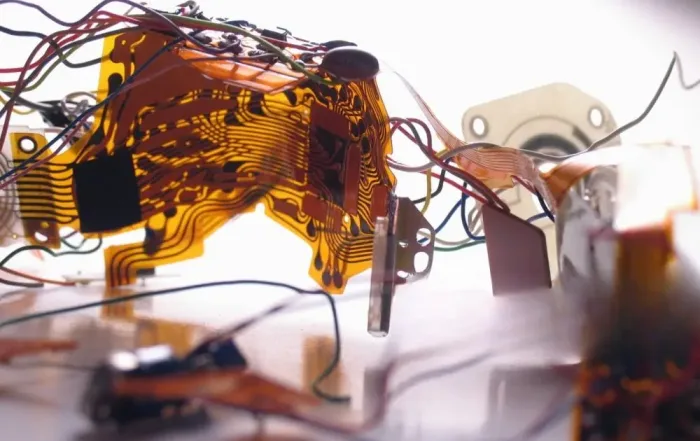

A primary function of high-performance tapes in electronics is to facilitate thermal management. They are designed to transfer heat away from sensitive components like computer processors, LEDs, and power supplies, moving it toward a heat sink or enclosure. These “thermal management tapes” often contain thermally conductive materials, such as ceramic or aluminum fillers, within their adhesive compound, enabling them to efficiently conduct heat away from the source. In applications like LED lighting and 3D printing, high-temperature double-sided tapes are used to bond components to heat sinks, providing both a strong mechanical connection and an effective thermal interface. Additionally, these tapes are electrically insulating, which prevents the possibility of short circuits and adds a critical layer of safety.

The Material Science Of Functional Tapes

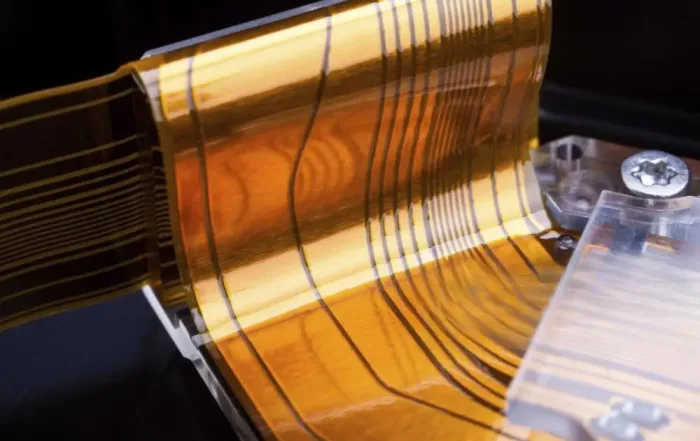

The performance of a high-temperature tape is determined by the material science behind its backing and adhesive system. Different materials are chosen for their specific properties to solve distinct engineering challenges. Polyimide tapes, for example, are a staple in electronics due to their exceptional thermal stability and superior electrical insulation properties, capable of withstanding temperatures up to 260°C (500°F). Our company provides various types of polyimide tapes that can withstand high temperatures of 260 degrees for 30 minutes. They are commonly used during soldering processes to protect delicate components and for wrapping cables and providing insulation for transformers and coils. Polyester tapes offer a balance of good electrical insulation and moderate temperature resistance, withstanding temperatures up to 218°C (425°F). Their mechanical strength makes them useful for masking during processes like conformal coating, protecting circuits from chemicals, moisture, and dust. Aluminum foil tapes, with a pure aluminum backing, excel at thermal conductivity and heat reflection, with a service temperature range of up to 316°C (600°F). They are used in electronics for heat shielding, reflecting radiant heat away from sensitive components to prevent overheating and prolong their operational life. By understanding the unique properties of each material, engineers can select the right tape to address specific thermal, electrical, and mechanical challenges.

High-Temperature Tape Material and Property Comparison

| Backing Material | Adhesive Type | Key Properties | Continuous Temp. Range (C/F) | Example Applications |

|---|---|---|---|---|

| Polyimide (Kapton®) | Silicone, Acrylic | High dielectric strength, chemical & radiation resistance, dimensional stability | -269 to 400°C (-452 to 752°F) | PCB masking, electrical insulation, aerospace |

| Polyester (PET) | Silicone, Acrylic | Good electrical insulation, mechanical strength, chemical & UV resistance | -40 to 218°C (-40 to 425°F) | Conformal coating masking, LED packaging, automotive |

| Fiberglass (Woven/Knit) | Silicone | Extremely high-temperature resistance, flame-retardant, high tensile strength | Up to 1093°C (2000°F) | Thermal insulation for pipes, cables, furnaces |

| Teflon (PTFE) | Silicone, Acrylic | Non-stick, chemical & UV resistance, excellent electrical insulation | -90 to 280°C (-130 to 536°F) | Heat-sealing, electrical panels, chemical barriers |

| Aluminum Foil | Silicone, Acrylic | Thermally conductive, heat reflection, conforms to surfaces, moisture-resistant | -54 to 316°C (-65 to 600°F) | HVAC duct sealing, heat shielding, insulation |

| Crepe Paper | Rubber/Resin | Conformable, resists paint bleed-through, clean removal | Up to 163°C (325°F) | Automotive paint masking, high-temp paint-bake operations |

Beyond Heat Management: Additional Benefits

In addition to their thermal properties, these tapes offer a range of other advantages that enhance manufacturing processes and product reliability. For instance, double-sided adhesive tapes provide a clean, efficient, and space-saving solution for bonding electronic components like touchscreens, sensors, and batteries without the need for traditional fasteners. They are also crucial for process protection, used to mask sensitive areas of printed circuit boards (PCBs) and prevent contamination during soldering or other chemical processes. Furthermore, many high-temperature tapes are formulated to be resistant to chemicals, oils, and solvents, providing a durable barrier that protects components and wires from corrosion and environmental damage over time. This versatility makes them indispensable for a wide range of electronic applications, from consumer goods to complex aerospace systems.

Choosing The Right Tape For Your Application

Selecting the ideal high-temperature tape for a specific electronic application requires a careful evaluation of its performance characteristics. Factors such as a tape’s thermal tolerance, electrical properties, adhesion strength, and resistance to chemical degradation must all be taken into account. A tape that works for heat shielding might not be suitable for electrical insulation, while a tape used for component assembly needs a different balance of properties than one used for masking. By consulting with an experienced tape manufacturer, engineers and designers can ensure they choose a product that not only meets their technical specifications but also contributes to the overall safety and performance of their final product. The right tape is a solution that can help extend component lifespan and ensure a product’s integrity in the most demanding environments.

Share This Article

Latest Articles

What Is Polyimide Tape Used For in Industrial and Technical Applications

What Is Polyimide Tape Used For in Industrial and Technical Applications [...]

Kapton Tape Explained: Composition, Applications, and Temperature Resistance

Kapton Tape Explained: Composition, Applications, and Temperature Resistance Kapton tape is a high-performance adhesive [...]

Polyimide Tape for 3D Printing Achieving Strong and Stable Bed Adhesion

Polyimide Tape for 3D Printing Achieving Strong and Stable Bed Adhesion Why Polyimide [...]