Acrylic polyimide tape

One-side coated with silicone-free acrylic PSA on a PI film, then laminated and slit. Core value: solves silicone contamination from silicone PI tape, ideal for precision electronic processes and high-temp clean masking. A key auxiliary material for PCBs, semiconductors, FPCs, etc.

- Strong, Versatile Adhesion: Bonds well to metals, plastics, glass; long-lasting strength with shear/aging resistance.

- Temp & Weather Durability: -60℃~175℃ (short-term 260℃); UV, humidity, and heat resistant for stable performance.

- Clean, Low Contamination: Silicone-free (selected models); low outgassing/ions; residue-free peeling for clean electronic processes.

- Reliable Insulation: H-class insulation with high dielectric strength and volume resistivity for safe electrical isolation.

- Chemical Resistance: Withstands weak acids/bases, alcohol, and common solvents; suitable for chemical masking/corrosion protection.

- Process-Friendly: Easy to die-cut/apply; compatible with automated lines to boost efficiency.

Product Selling Points

1. Silicone-Free Cleaning, Avoiding Process Risks

- Silicone-free acrylic adhesive: Eliminates migration; no post-process interference

- RoHS/halogen-compliant, low outgassing/ions; high-cleanliness use (PCBs, semiconductors, medical/aerospace)

2. High-Temperature Stability, Strong Durable Adhesion

- PI substrate: -60℃~175℃ (260℃ short-term, reflow/wave soldering); no delamination

- Strong adhesion to FR-4/metals/plastics; shear/aging-resistant; outdoors/humid-proof

3. Insulation Protection, Precision Adaptation

- H-class insulation (≥15kV/mm, ≥10¹⁴Ω・cm); gold finger/coil insulation

- High-strength substrate; precise die-cutting; fits curves/automation; customizable (anti-static/flame-retardant/light-blocking)

Acrylic-based Polyimide Tape Specification Sheet

| Effective Width (MM) | Subject to actual shipment specifications</ | ||||

|---|---|---|---|---|---|

| ITEM UNIT |

KA03D34 | KA04D19 | KA05D14 | KA06D25 | TEST METHOD |

| Dimension & Tolerances / Product Dimension | |||||

| 1. Color | Amber | Amber | Tea Color | Amber | |

| 2. Thickness (MM) | 0.030±0.003 | 0.040±0.004 | 0.050±0.005 | 0.065±0.005 | GB/T 7125-1999 |

| 3. Inside Diameter of Roll (MM) | 76.2±0.4 | 76.2±0.4 | 77±1 | 77±1 | |

| 4. Length (M) | Customized | Customized | 100 | Customized | |

| Composition / Product Design | |||||

| 1. Backing | PI | PI | PI | PI | |

| 2. Backing Thickness (MM) | 0.020±0.002 | 0.025 | 0.025 | 0.05 | GB/T 7125-1999 |

| 3. Adhesive | Acrylic | Acrylic | Acrylic | Acrylic | |

| Physical & Chemical Properties / Technical Data | |||||

| 1. Tack (N/24mm) | – | – | ≥1 | – | GB/T 3125-2014 |

| 2. 180° Peel adhesion (N/25MM) | 6±3 | 2-6 | ≥7 | 2-6 | GB/T 2792-1998 |

| 3. Holding Power (hr) | – | – | ≥12 | – | GB/T 4851-1998 |

| 4. Tensile Strength (Mpa) | – | – | ≥60 | – | GB/T 7753-87 |

| 5. Elongation (%) | – | – | ≥20 | – | GB/T 7753-87 |

| 6. Temperature Resistance (℃) | 150℃/30min (No deformation/wrinkling after baking with aluminum foil) | 260℃/30mins (No adhesive residue) | 130℃/0.5H (Flat, no warping or shrinkage) | 200℃/30mins (No adhesive residues) | |

| 7. Electrolyte Resistance (hr) | No falling off/dissolving after soaking in electrolyte (85℃/4hr) | – | >24 (No falling off, retains stickiness after soaking at room temperature) | – | |

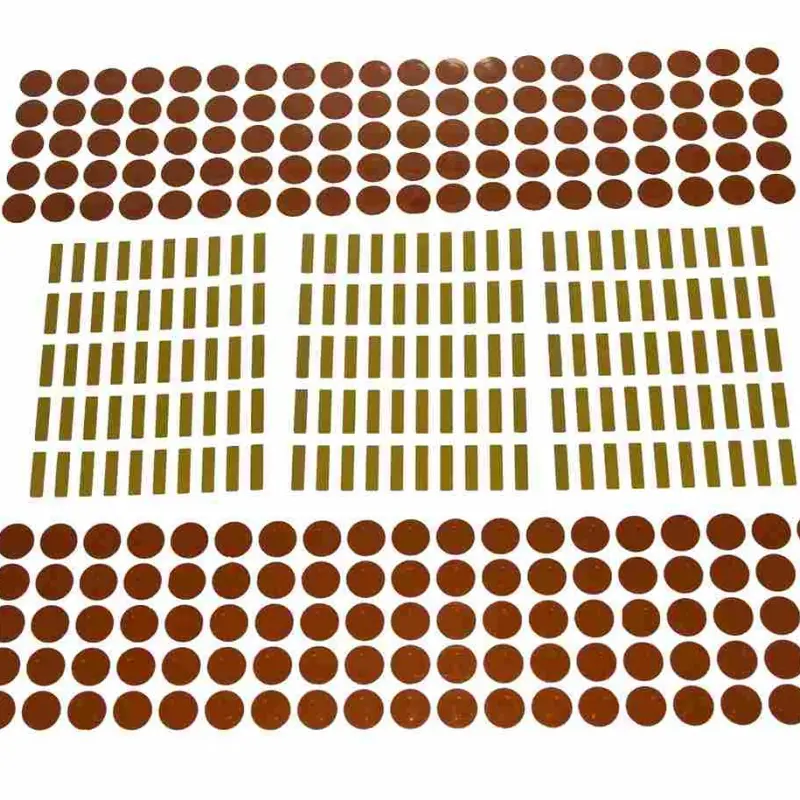

Customizable styles

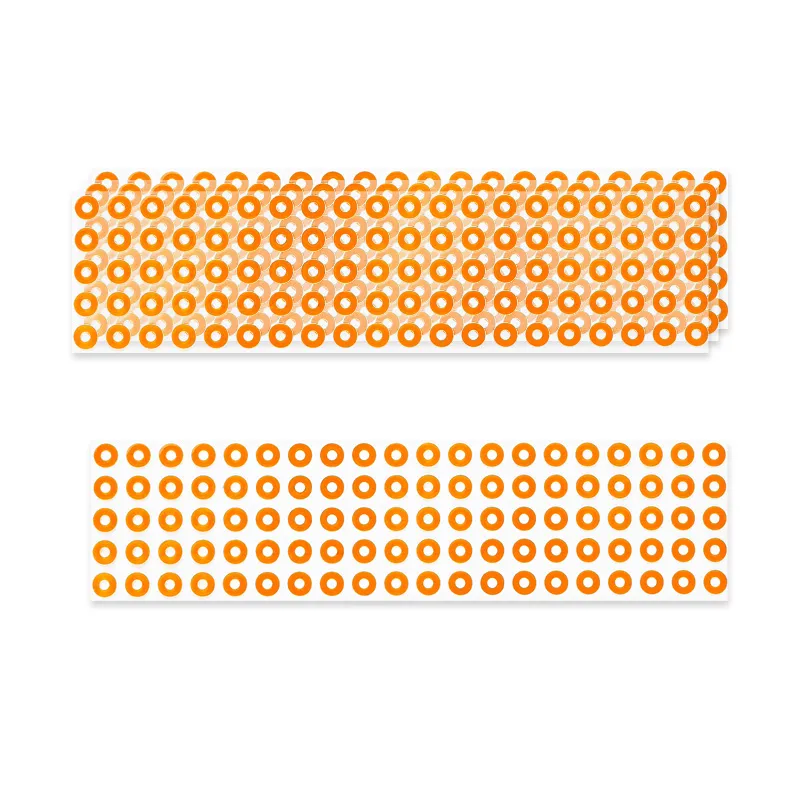

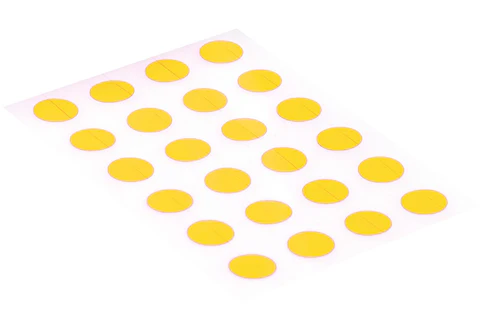

1. Polyimide CIRCLES

Primarily used for localized masking and protection in electronic manufacturing, such as:

- precise masking during PCB wave soldering and gold finger spraying (to prevent solder joints/gold fingers from being contaminated);

- protection of specific areas in high-temperature spraying processes (high temperature resistance, easy peeling, and no residue).

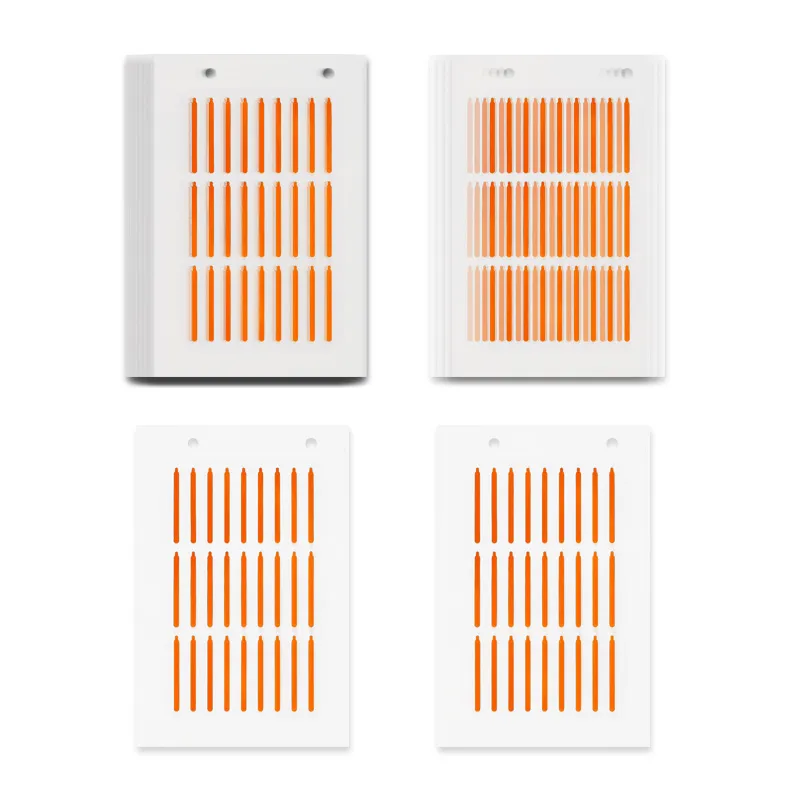

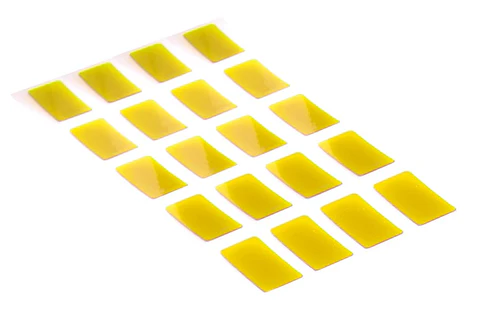

2. Polyimide rectangular

It belongs to the category of die-cut custom shapes and is commonly used for:

- fixing and insulating the positive/negative tabs of lithium batteries;

- component masking in SMT (Surface Mount Technology) processes;

- partial insulation wrapping of motor and transformer coils.

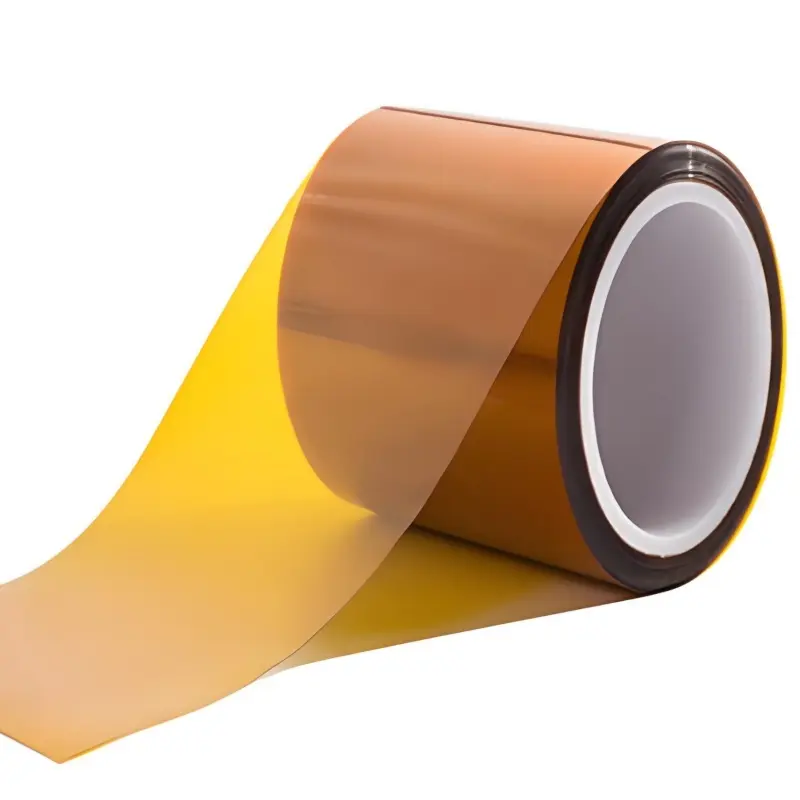

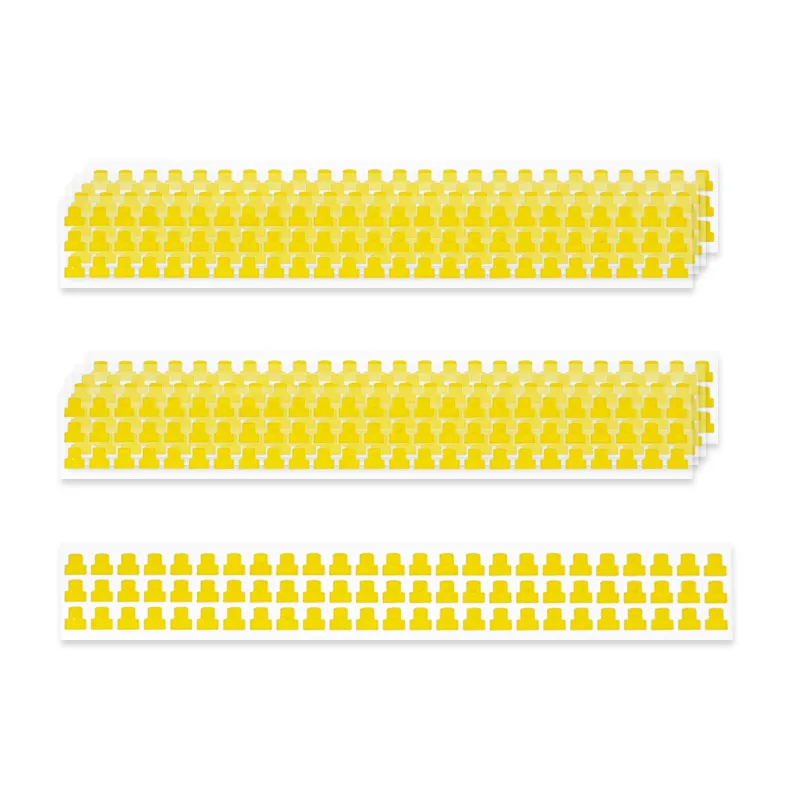

3. Polyimide Rolls

Supplied in roll form, suitable for large-area/continuous processing scenarios:

- Coil insulation wrapping for motors and transformers (resistant to high and low temperatures, high insulation level);

- Substrate for flexible printed circuits (FPC);

- High-temperature insulating sleeves for cables.

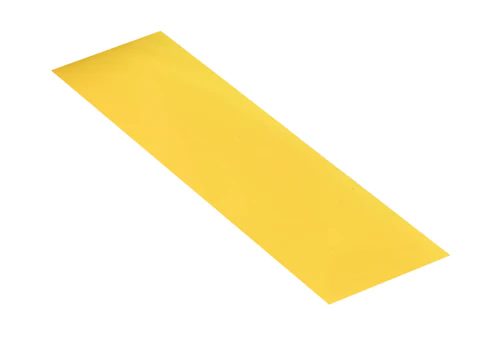

4. Polyimide Sheets

Suitable for large-area/custom-size insulation/substrate needs:

- Encapsulation substrates for high-temperature heating films (such as heating elements in aerospace/medical equipment);

- Sample support films for X-ray fluorescence spectroscopy (XRF) analysis;

- Structural support and overall protection of gold fingers for flexible circuit boards.

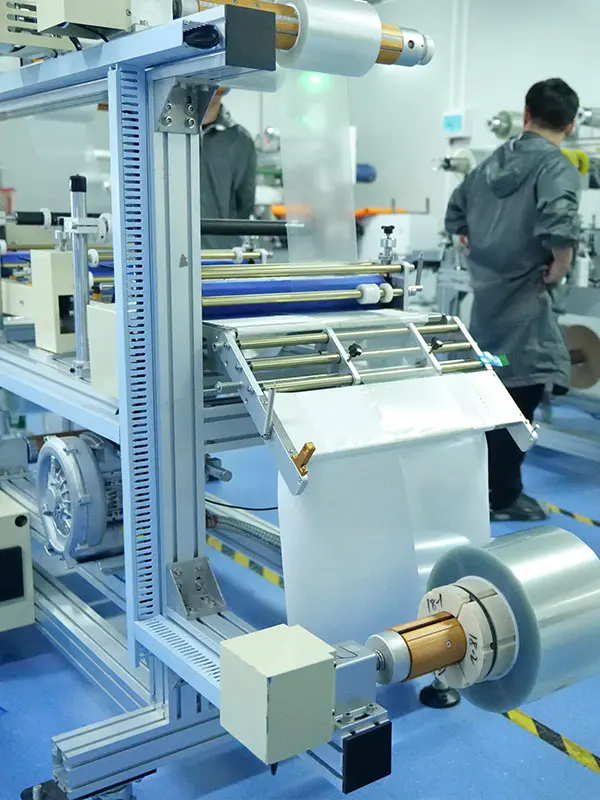

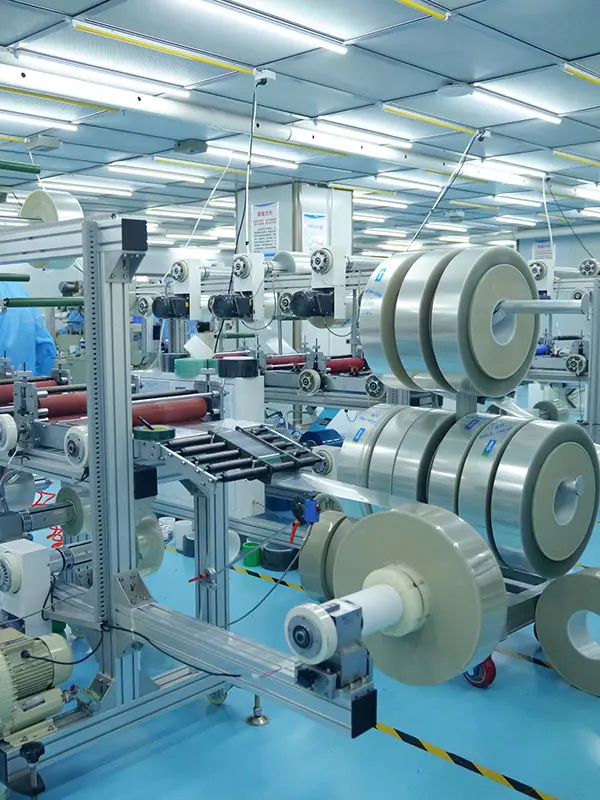

Our Production Equipment

Jiujiang Leadcomp Co., Ltd. has many years of experience in the manufacturing of high-temperature tapes. Our factory is equipped with advanced slitting, die-cutting, and coating equipment, enabling large-scale, precise, and high-quality production. Each roll of tape undergoes rigorous quality control to ensure its reliability and consistency in industrial applications.

Customer Success Stories

Jiujiang Leadcomp Co., Ltd. provides high-quality ODM and OEM tape solutions for numerous industries, customizing die-cut tape products to meet each customer’s unique needs. With years of experience in precision die-cutting, we pride ourselves on advanced processes and attention to detail. The following showcases our superior die-cutting technology and samples, reflecting our relentless pursuit of quality and precision.