Black Polyimide Tapes

Black Polyimide tape is a critical, high-performance material known best by the trade name Kapton. Unlike ordinary tapes designed for bonding or low-temperature masking, polyimide tape is an engineered polymer designed to maintain its integrity, strength, and electrical properties under conditions that would instantly melt, brittle, or degrade almost any other plastic or adhesive. The black variant, however, offers specialized optical properties:

Applications: These specialized properties make it indispensable for masking sensitive surfaces on optical sensors and camera modules to prevent light leakage (crosstalk), lining the interior of aerospace instruments to absorb stray light, and providing high-temperature electrical insulation in electronics.

Functions: lt features extreme thermal endurance (withstanding temperatures over260°C), superior electrical insulation, and critically, 100% light shielding (opacity) andlow reflectivity due to its matte finish.

Product Selling Points

1. PI Substrate + Dual Black Functional Enhancement

- PI substrate: Withstands 260℃, H-class insulation (dielectric strength ≥120kV/mm)

- Black formulation: Full light blocking (visible transmittance <0.1%) + low reflectivity, ideal for optical/backlight modules

- High tear strength + silicone adhesive: Residue/discoloration-free removal at high temps, protecting PCB gold fingers/battery tabs

2. High-Temperature Process + Dual Light Shielding Protection

- Withstands high-temp processes (e.g., SMT reflow soldering), enabling simultaneous shielding + light blocking to cut steps & boost efficiency

- Stable performance (-60℃ to 260℃); chemical/radiation-resistant, suitable for new energy/avionics extreme environments

3. Precision Bonding + Dual Customization Flexibility

- Uniform adhesive (excellent conformability): Fits complex curves/irregular components; high-precision die-cutting supports automated assembly

- Customizable (low-static, flame-retardant versions): Meets sensitive electronic component needs & safety compliance

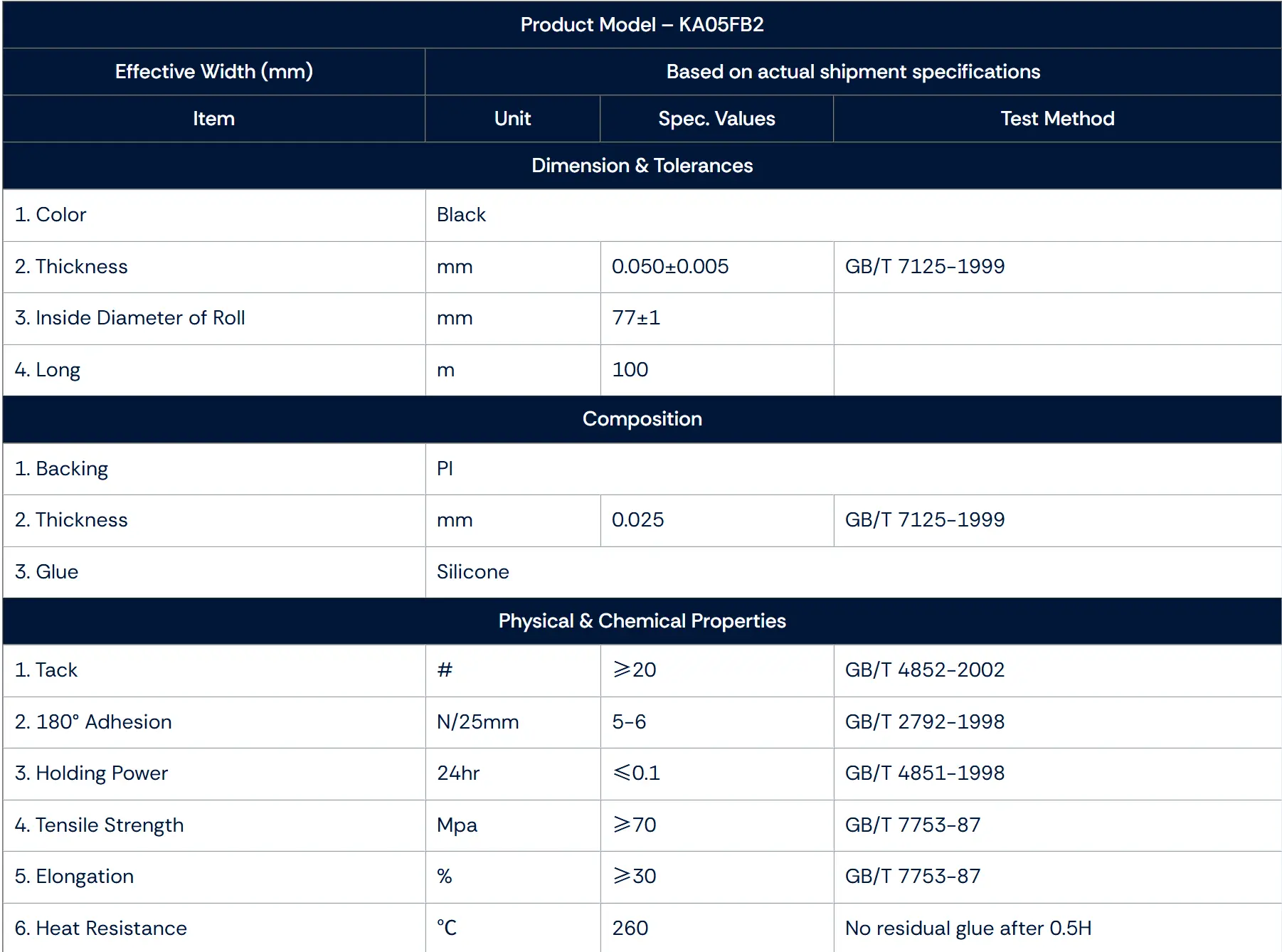

Specifications of Black Polyimide Tape

| Product Model – KA05FB2 | |||

|---|---|---|---|

| Effective Width (mm) | Based on actual shipment specifications | ||

| Item | Unit | Spec. Values | Test Method |

| Dimension & Tolerances | |||

| 1. Color | Black | ||

| 2. Thickness | mm | 0.050±0.005 | GB/T 7125-1999 |

| 3. Inside Diameter of Roll | mm | 77±1 | |

| 4. Long | m | 100 | |

| Composition | |||

| 1. Backing | PI | ||

| 2. Thickness | mm | 0.025 | GB/T 7125-1999 |

| 3. Glue | Silicone | ||

| Physical & Chemical Properties | |||

| 1. Tack | # | ≥20 | GB/T 4852-2002 |

| 2. 180° Adhesion | N/25mm | 5-6 | GB/T 2792-1998 |

| 3. Holding Power | 24hr | ≤0.1 | GB/T 4851-1998 |

| 4. Tensile Strength | Mpa | ≥70 | GB/T 7753-87 |

| 5. Elongation | % | ≥30 | GB/T 7753-87 |

| 6. Heat Resistance | ℃ | 260 | No residual glue after 0.5H |

Customizable styles

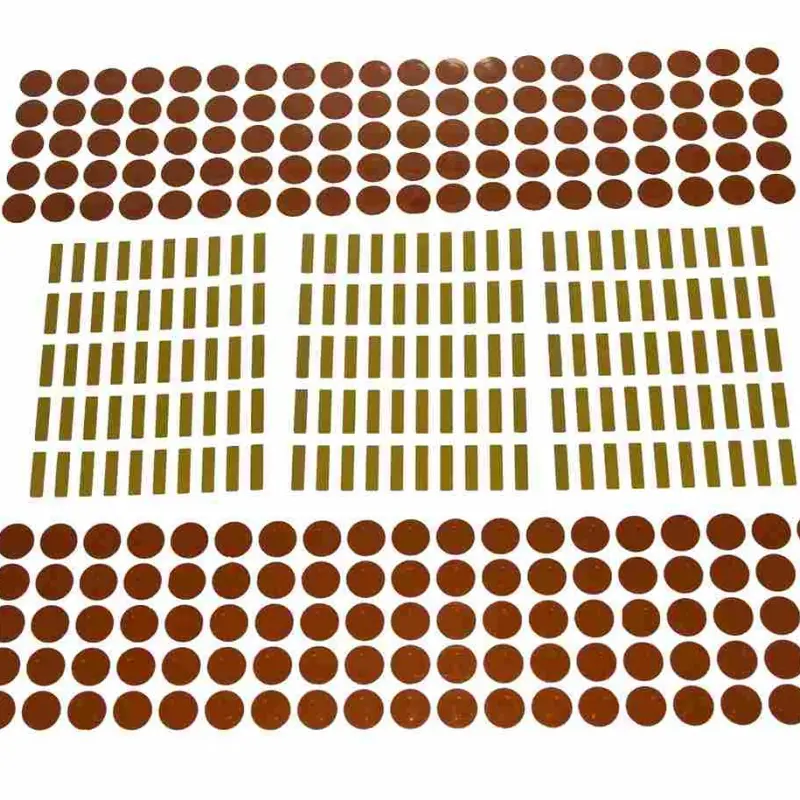

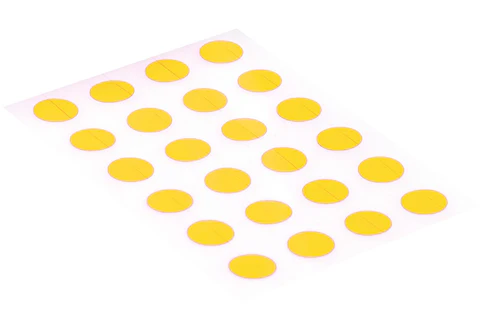

1. Polyimide CIRCLES

Primarily used for localized masking and protection in electronic manufacturing, such as:

- precise masking during PCB wave soldering and gold finger spraying (to prevent solder joints/gold fingers from being contaminated);

- protection of specific areas in high-temperature spraying processes (high temperature resistance, easy peeling, and no residue).

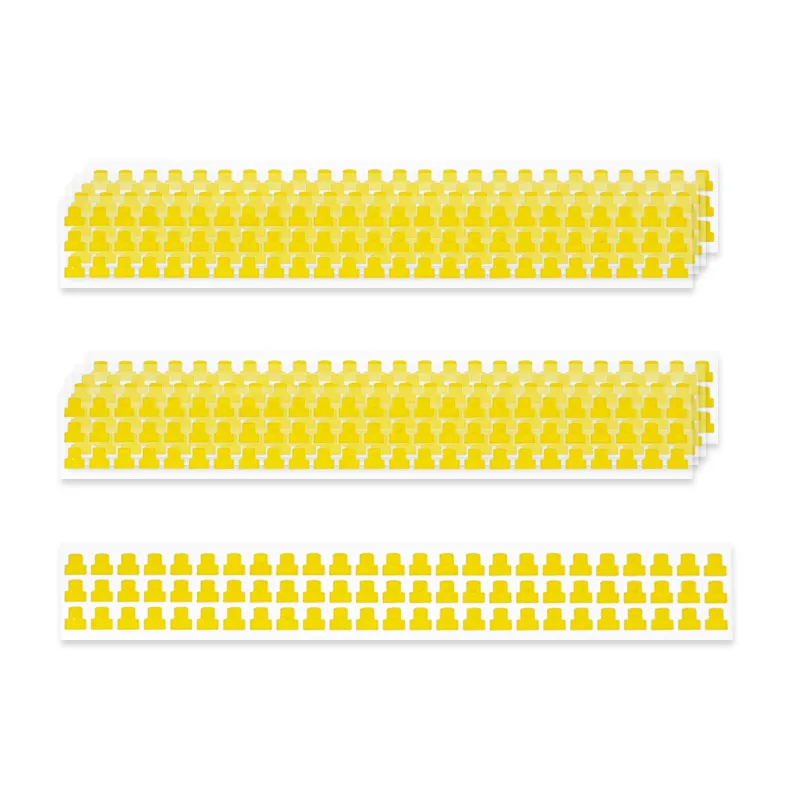

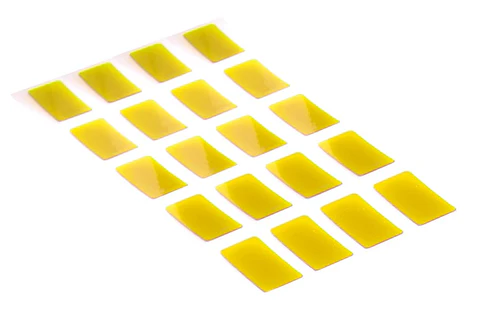

2. Polyimide rectangular

It belongs to the category of die-cut custom shapes and is commonly used for:

- fixing and insulating the positive/negative tabs of lithium batteries;

- component masking in SMT (Surface Mount Technology) processes;

- partial insulation wrapping of motor and transformer coils.

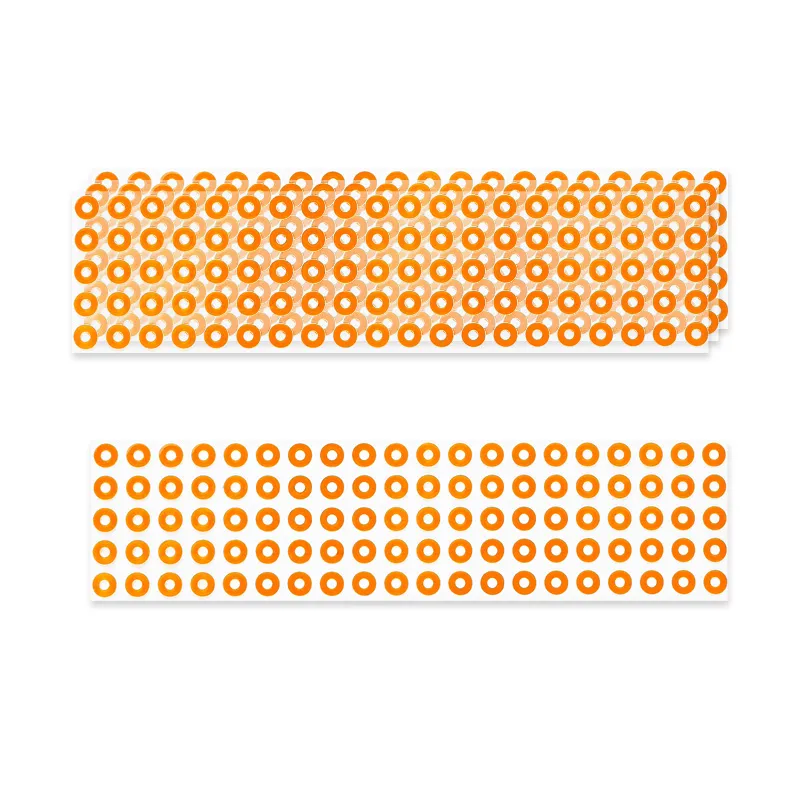

3. Polyimide Rolls

Supplied in roll form, suitable for large-area/continuous processing scenarios:

- Coil insulation wrapping for motors and transformers (resistant to high and low temperatures, high insulation level);

- Substrate for flexible printed circuits (FPC);

- High-temperature insulating sleeves for cables.

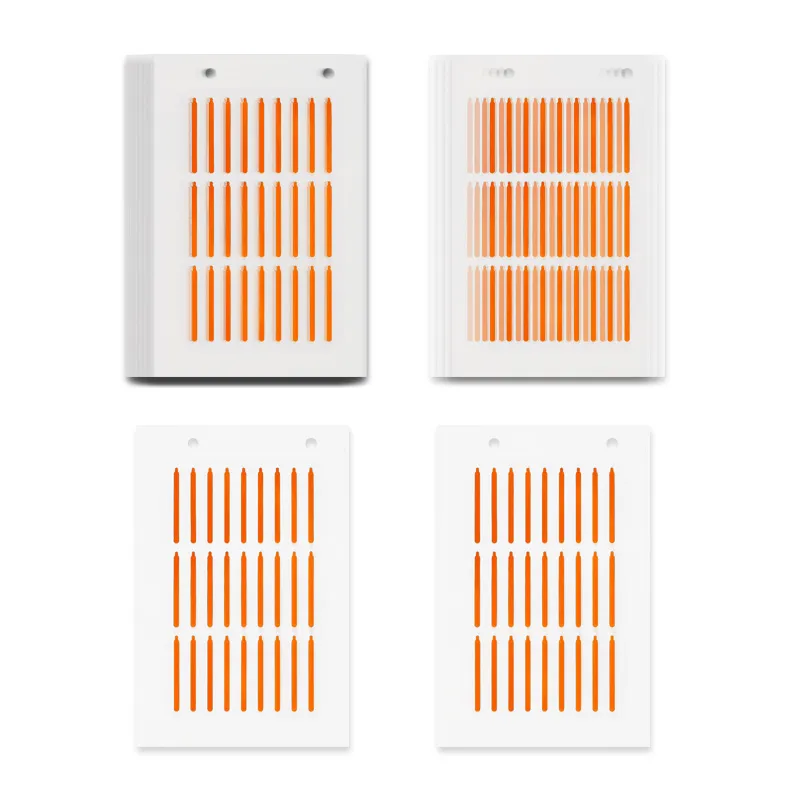

4. Polyimide Sheets

Suitable for large-area/custom-size insulation/substrate needs:

- Encapsulation substrates for high-temperature heating films (such as heating elements in aerospace/medical equipment);

- Sample support films for X-ray fluorescence spectroscopy (XRF) analysis;

- Structural support and overall protection of gold fingers for flexible circuit boards.

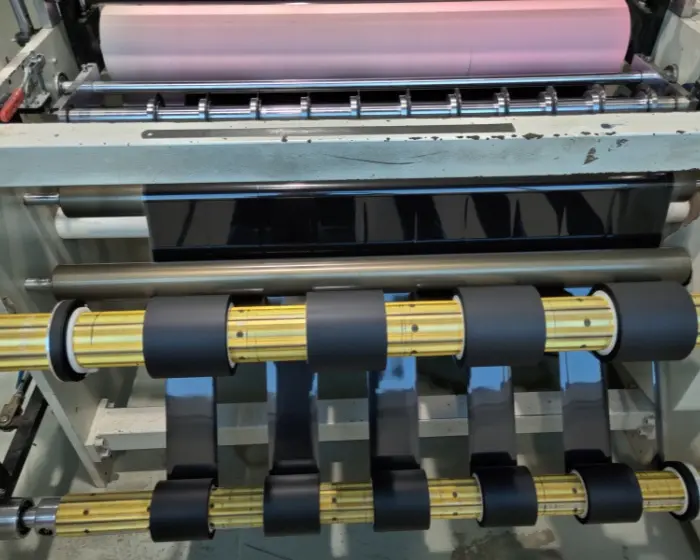

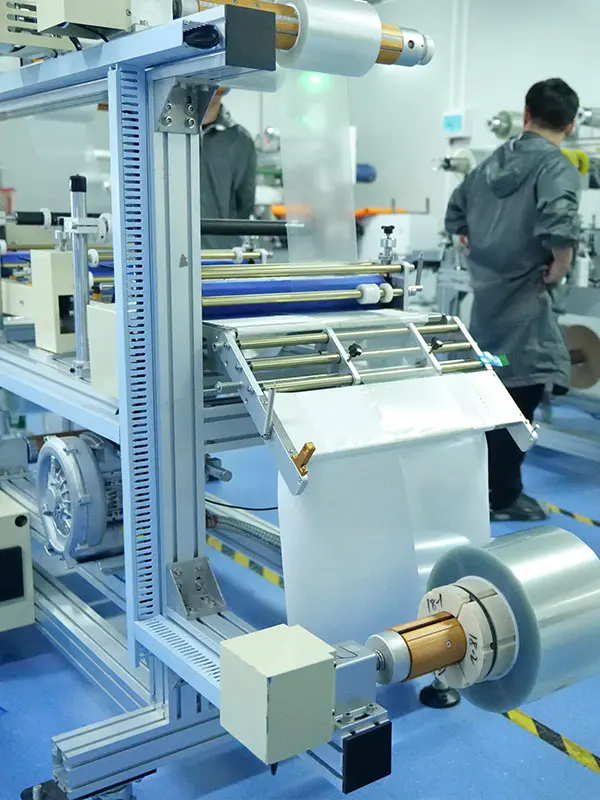

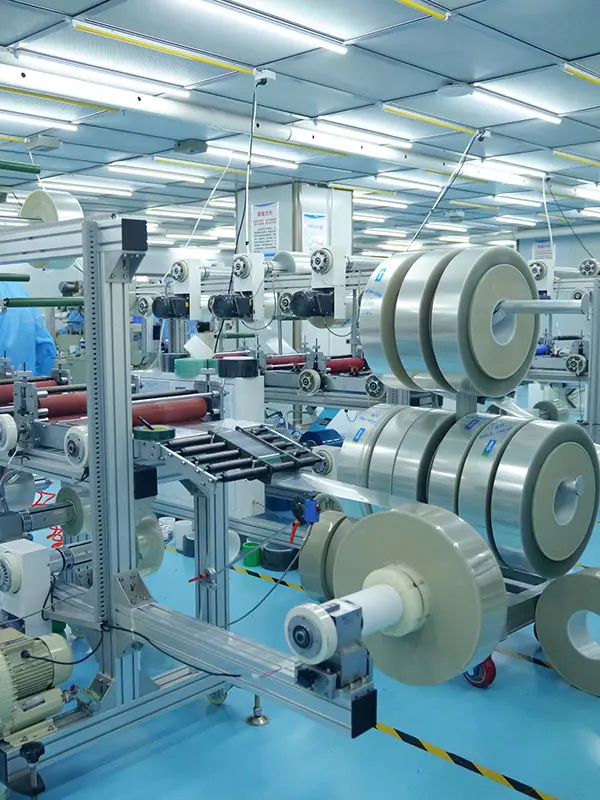

Our Production Equipment

Jiujiang Leadcomp Co., Ltd. has many years of experience in the manufacturing of high-temperature tapes. Our factory is equipped with advanced slitting, die-cutting, and coating equipment, enabling large-scale, precise, and high-quality production. Each roll of tape undergoes rigorous quality control to ensure its reliability and consistency in industrial applications.

Customer Success Stories

Jiujiang Leadcomp Co., Ltd. provides high-quality ODM and OEM tape solutions for numerous industries, customizing die-cut tape products to meet each customer’s unique needs. With years of experience in precision die-cutting, we pride ourselves on advanced processes and attention to detail. The following showcases our superior die-cutting technology and samples, reflecting our relentless pursuit of quality and precision.