From Powder Coating To Plating: The Critical Role Of High-Temperature Masking Tapes

In high-stakes industrial applications like powder coating and electroplating, achieving a flawless finish is paramount. These engineered tapes are a critical tool for protecting surfaces and ensuring clean, residue-free removal after exposure to extreme heat and harsh chemicals, safeguarding components and streamlining production.

The Challenge of High-Temperature Processes

Modern industrial finishing processes, such as powder coating and paint-bake operations, subject parts to extreme temperatures. For example, automotive paint-bake operations can reach temperatures up to 163℃ (325℉). The tape must prevent paint bleed-through and survive thermal stress without degrading, melting, or leaving a sticky residue, which are common causes of costly rework.

The Material Science of a Clean Finish

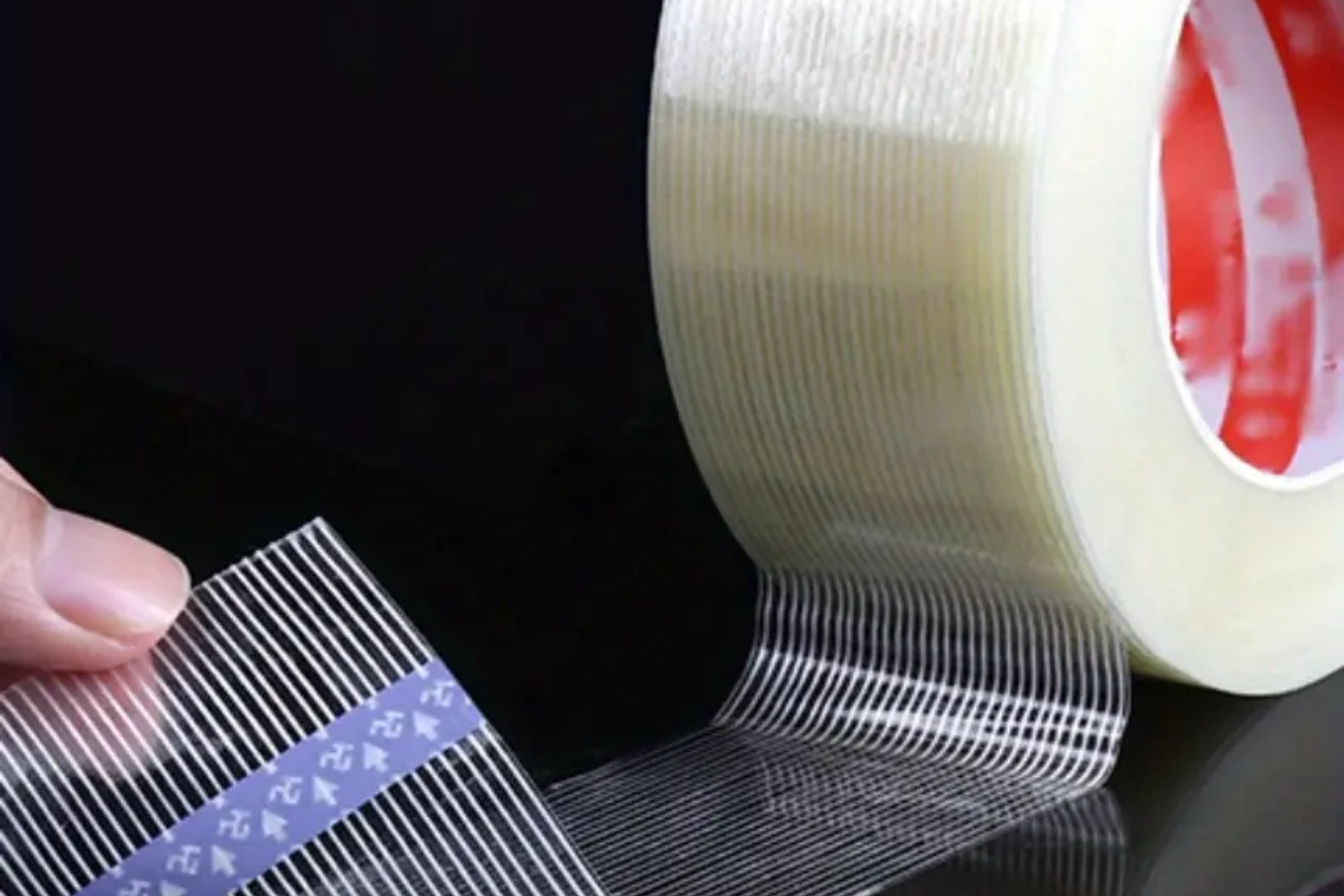

The tape’s effectiveness is rooted in its specific backing and adhesive materials. Crepe Paper Tapes offer high conformability for irregular surfaces and general paint masking. Conversely, Polyester (PET) tapes provide exceptional mechanical strength and chemical resistance, making them essential for masking during conformal coating in electronics manufacturing. This material choice is what ensures a clean, residue-free removal, simplifying the production manager’s process.

Beyond The Paint Booth: Versatile Applications

High-temperature tapes solve challenges across diverse industries, ensuring safety and reliability:

Key Properties for High-Performance Selection

Understanding the specialized nature of each tape material is crucial. Polyimide (PI) offers superior electrical insulation and thermal stability for high-end electronics, while Crepe Paper is the conformable, low-cost option for general paint masking.

Data Table

| Backing Material | Adhesive Type | Continuous Temp. Range (°C) | Key Properties |

|---|---|---|---|

| Polyimide (Kapton®) | Silicone, Acrylic | -269 to 260 | High dielectric strength, chemical & radiation resistance |

| Polyester (PET) | Silicone, Acrylic | -40 to 200 | Good electrical insulation, mechanical strength, chemical & UV resistance |

| Crepe Paper | Rubber/Resin | Up to 200 | Conformable, resists paint bleed-through, clean removal |

Optimizing Manufacturing: A Solution-First Approach

Choosing the right tape requires a holistic view that considers adhesion strength, chemical compatibility, and ease of removal. The right choice leads to quick, one-piece removal without residue, significantly reducing labor time and improving quality control. This efficiency is key to streamlining processes and gaining a competitive advantage.