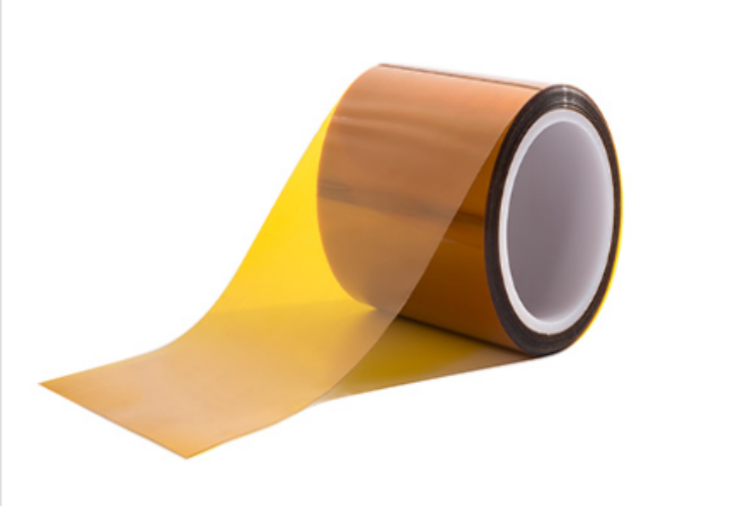

High-temperature double-sided tape

High-temperature double-sided tape offers excellent bonding properties to metals, plastics (PP, PE, ABS), and foam. It also offers excellent resistance to heat, weather, and curved surfaces.

Production Process Flow

From raw materials to finished product, every step is rigorously controlled to ensure consistent and reliable performance.

The process begins with the careful selection of three primary components:

Carrier Film (Substrate): This is the central layer that provides dimensional stability and strength. For high-temperature applications, common carriers include:

PI Film (Polyimide): For the highest temperature resistance (up to 260°C) and excellent electrical insulation.

PET Film (Polyester): A cost-effective choice for mid-range high temperatures (up to 180°C).

Adhesive: A high-performance Silicone pressure-sensitive adhesive is typically used for both sides. It is chosen for its ability to maintain a strong bond at high temperatures and its clean removability characteristics.

Release Liners: Two separate release liners are required, one for each adhesive side. These are typically PET or paper films coated with a release agent (often also silicone-based) that allows the tape to be unwound without the adhesive sticking to itself. The two liners often have different release forces to make application easier (differential release).

High-performance silicone adhesive is prepared by mixing raw silicone polymers, tackifying resins, cross-linking agents, and catalysts in a large reactor. Solvents are used to dissolve the components and achieve the precise viscosity needed for the coating heads. The formulation is critical for achieving the desired balance of peel, tack, and shear strength at high temperatures.

In the first major step, the formulated liquid silicone adhesive is applied to the first release liner using a precision coating machine. The liner acts as a temporary web to carry the adhesive through the process. The coated liner then passes through a drying oven to evaporate the solvents.

Once the first adhesive layer is applied to its liner and is in a semi-cured state, the primary carrier film (e.g., Polyimide or PET) is carefully laminated onto the exposed adhesive surface using pressure rollers. This creates a two-layer structure: Release Liner #1 / Adhesive Layer #1 / Carrier Film.

The structure is then flipped, and the second layer of silicone adhesive is coated directly onto the exposed side of the carrier film. Immediately after coating, the second release liner is laminated onto this new adhesive layer. This completes the full five-layer construction: Release Liner #1 / Adhesive Layer #1 / Carrier Film / Adhesive Layer #2 / Release Liner #2.

The complete tape construction is passed through a long, multi-zone curing oven. The high temperatures in the oven activate the cross-linking agents in both adhesive layers, causing them to cure fully. This process builds the adhesive’s internal strength (cohesion) and locks in its high-temperature performance characteristics.

The fully cured, wide “jumbo roll” is transferred to a slitting machine. High-speed rotary blades cut the material into narrow rolls of the specified width. The tape is then rewound onto individual plastic or paper cores to the desired length, creating the finished product.

Throughout the process, rigorous quality checks are performed. Key tests for high-temperature double-sided tape include:

Total Thickness: Measuring the thickness of the final construction.

Peel Adhesion: Testing the bond strength of each adhesive side to a standard surface (like stainless steel).

Shear Strength: Measuring the adhesive’s ability to resist slippage under load, especially at elevated temperatures.

Temperature Resistance: Exposing the tape to its maximum rated temperature and then testing its bond integrity.

After passing all quality inspections, the finished rolls are packaged, labeled with product information and batch numbers, and stored in a climate-controlled warehouse to await shipment.

High-temperature double-sided tape Series Specification Sheet

| Name | ltem No.Model | Material | Colour | Adhesive | standard size | Adhesion | Tensile strength | Temperature resistance | |

| thick/mm | long/m | (N/25mm) | (N/25mm) | ℃ | |||||

| Polyester double-sided high-temperature tape | DS83 | PET | Yellow | Acrylic | 0.03 | / | 7 | 50 | 200 |

| Glass cloth double-sided high-temperature tape | DS20GL | Glass Cloth | White | Silicone | / | / | 6↑ | 320↑ | 200 |

| Cotton paper double-sided high-temperature tape | DS309H | Tissue Paper | White | Acrylic | 0.09 | 50 | 12 | 15 | 100 |

| Polyimide double-sided tape | DS10K | PI | Golden | Silicone | / | / | 3.5↑ | 170↑ | 250 |

| Foam double-sided tape | SP81G | PE | Green | Acrylic | 1 | / | 20 | 30 | 80 |

| Foam double-sided tape | SPE30H1 | EVA | Red | Hot melt adhesive | 3 | / | 14 | / | 80 |

| Non-substrate double-sided tape | DSW05G | / | White | Acrylic | 0.05 | / | 14 | / | 200 |

Functions, Uses, and Applications

High-temperature double-sided tape is an advanced bonding solution for challenging industrial applications. Its core function is to provide a strong, permanent bond between two surfaces that maintains its integrity during and after exposure to extreme heat.

Functions, Uses, and Applications

High-temperature double-sided tape is an advanced bonding solution for challenging industrial applications. Its core function is to provide a strong, permanent bond between two surfaces that maintains its integrity during and after exposure to extreme heat.

Quality Standards & Certifications

Jiujiang Leadcomp Co., Ltd. is committed to delivering the highest quality products, a promise backed by strict internal standards and authoritative third-party certifications.