Kapton Tape Explained: Composition, Applications, and Temperature Resistance

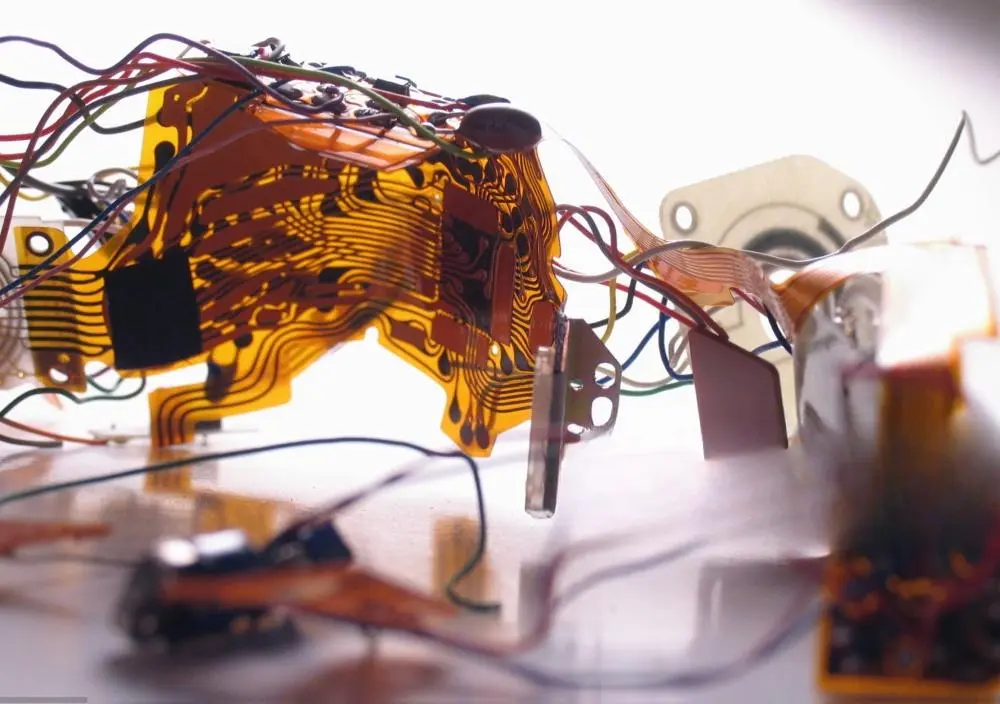

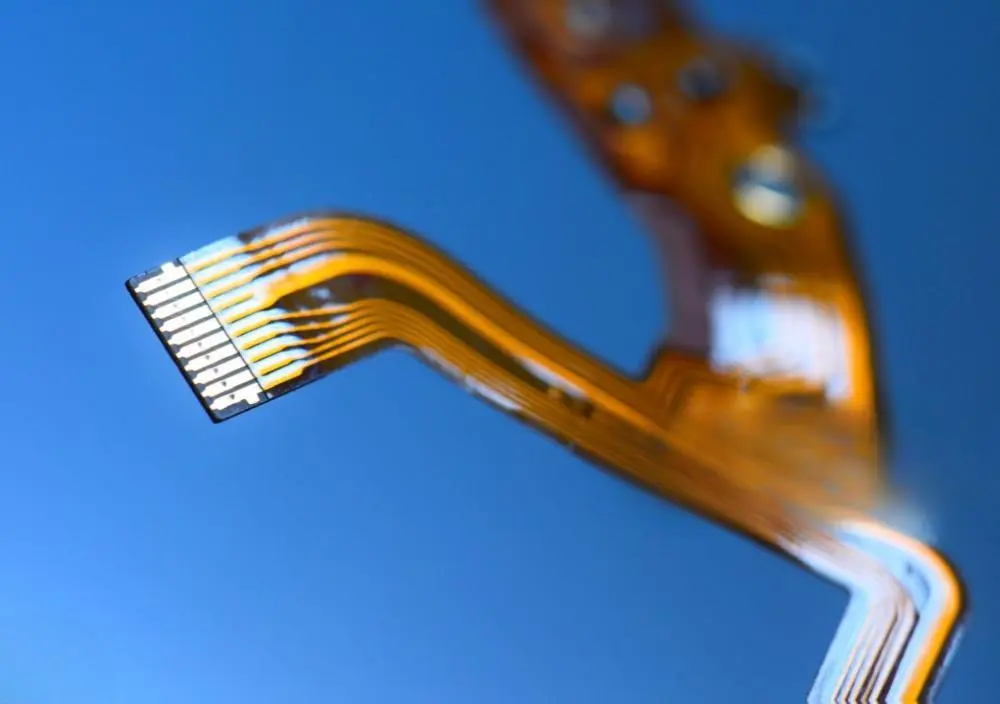

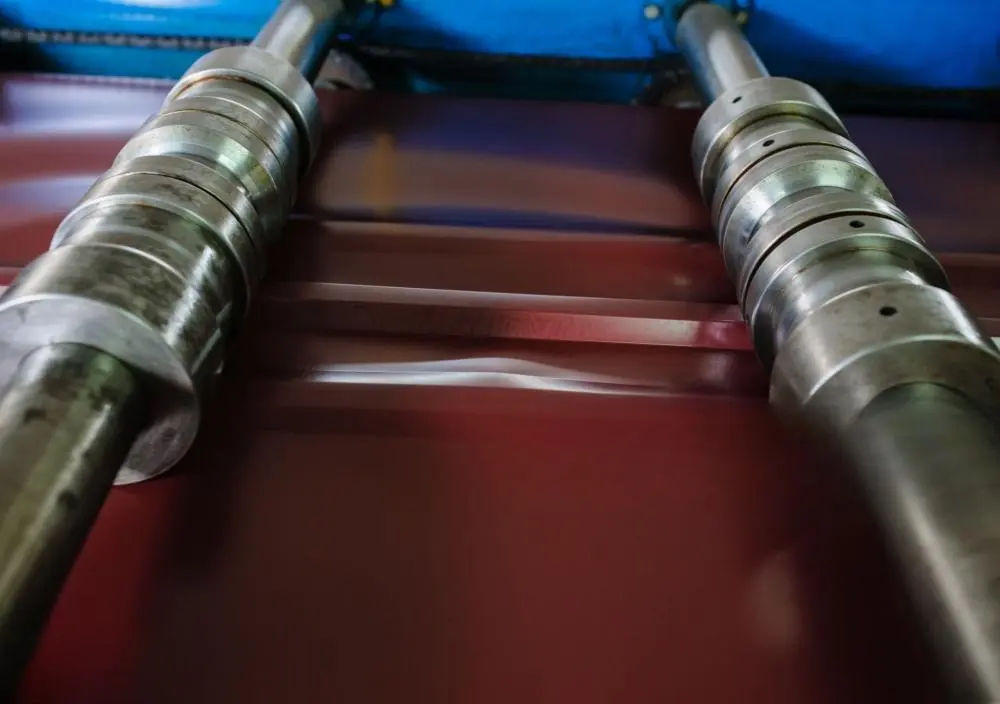

Kapton tape is a high-performance adhesive tape widely recognized for its exceptional thermal stability, electrical insulation, and chemical resistance. It is commonly used in electronics, industrial manufacturing, and other demanding environments where conventional adhesive tapes fail. To better understand why Kapton tape performs so reliably, it is important to examine its material composition, typical uses, and behavior under extreme temperatures.

01. What is Kapton Tape Made Of?

Kapton tape is made of a polyimide film backing combined with a high-temperature silicone adhesive.

02. What is Kapton Tape Used For?

03. At What Temperature Does it Melt?

Polyimide High Temperature Adhesive Tape for Masking, Soldering and Electrical Work

Kapton tape is a specialized high-temperature adhesive tape designed for demanding environments. It is made from polyimide film with a silicone adhesive, used extensively in electronics, 3D printing, and industrial manufacturing, and capable of withstanding extreme heat without melting. Understanding what Kapton tape is made of, what it is used for, and how it behaves at high temperatures helps explain why it remains a preferred solution for engineers and manufacturers worldwide.