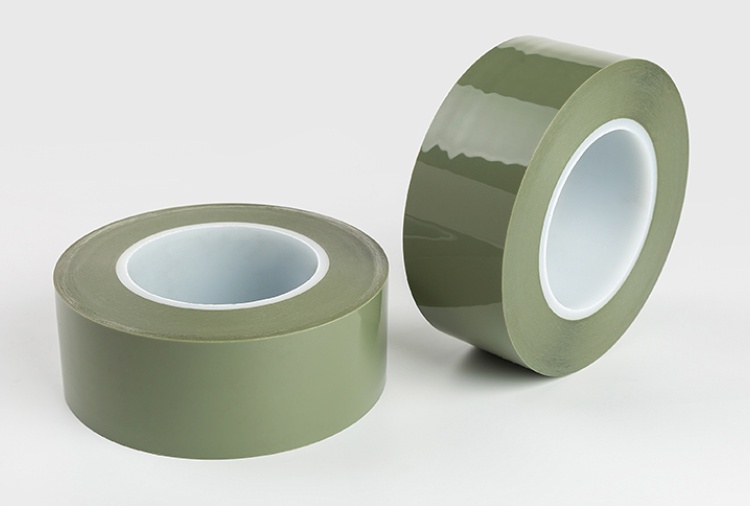

Ni-MH battery tape

High-temperature tape for lithium batteries is made of insulating materials (PP, PET, PI films) as the base material, with a special acrylic adhesive resistant to lithium battery electrolytes coated on it. Its thicknesses are 0.016mm, 0.020mm, 0.03mm, 0.035mm, 0.04mm, and 0.05mm.

Features: High temperature resistance, alkali resistance, no warping, no discoloration, and good conformability.

Application: Insulation and fixation inside nickel-metal hydride batteries.

Detailed description

Nickel-Metal Hydride (Ni-MH) battery tape uses thickened polypropylene film as the base material, coated with alkali-resistant rubber pressure-sensitive adhesive. It is mainly used for insulation and fixation inside nickel-metal hydride batteries.

Related Specifications

| Name | ltem No.Model | Material | Colour | Adhesive | standard size | Adhesion Strength | Tensile Resistance | Exten- sibility | Voltagewithstand | Temperature tolerance | ||

| thick/mm | wide/mm | long/m | N/25mm | N/25mm | % | ℃ | ||||||

| Ni-MH battery tape | PP09A | BOPP | Khaki | rubber | 580 | 100/200 | 3↑ | 5↑ | 100 | 50 | 4kv | 80 |

FAQ

Lens Protection Tape Series

Specialized for encapsulating resin eyeglass lenses during high-temperature curing processes. Key features include high transparency, residue-free removal, and heat resistance up to 130°C (e.g., JT8860 for blue-light-blocking lenses)

Lithium Battery Tape Series

Includes termination tapes (for electrode insulation), PACK tapes (bundle fixation), and tab lead tapes (welding point protection). Made from PI/PET films with electrolytic corrosion resistance, critical for cylindrical/pouch cell safety

LED Encapsulation High-Temperature Tape Series

Designed for LED epoxy resin filling and curing (e.g., MY68C transparent tape for digital tubes). Withstands 150–180°C, prevents overflow, and leaves no residue after peeling

Connector Tapes Series

Insulating tapes for electronic connectors and terminals, ensuring stability in soldering (reflow peak: 260–300°C). Commonly uses PI films for dielectric strength

Insulation & Fixation Tapes Series

Glass fiber-reinforced tapes for coil binding in motors/transformers, offering mechanical strength and flame retardancy (180–220°C continuous use)

High-Temperature Double-Sided Tape Series

Features acrylic/silicone adhesives on PI/PET bases. Used for bonding heat sinks, battery modules, and composite materials, withstanding 120–180°C long-term

Masking Tapes Series

Includes high-temp masking paper and PET green tapes for spray painting, powder coating, and PCB gold finger protection. Resists solvents, leaves sharp edges, and operates at 150–230°C

Teflon Tape Series

PTFE-based tapes with ultra-low friction and 260–300°C continuous resistance. Applied in non-stick industrial conveyors, food packaging seals, and chemical equipment lining

Yes, we can develop tailored solutions based on your sketches or ideas to address your business challenges.

The Company serves all customer segments, offering tailored solutions for large enterprises, small businesses, and individual users.

NiMH battery tape typically ranges in width from 4mm to 10mm and is approximately 0.06mm thick. Its key characteristics include resistance to electrolytes, acids, and alkalis, as well as excellent electrical insulation. It also offers moderate initial tack and adhesion, allowing it to adhere well to various battery components. Its moderate unwinding force allows it to adapt to various production process requirements. NiMH battery tape is primarily used to insulate and protect the positive tabs of NiMH batteries, preventing short circuits during the winding process and preventing adverse effects caused by contact between the tabs and the battery casing, thereby ensuring the performance and safety of NiMH batteries.

As a functional material tailored to the internal environment and process requirements of nickel-metal hydride batteries, nickel-metal hydride battery tape’s core properties revolve around insulation protection, environmental corrosion resistance, mechanical stability, and process adaptability. These key features include the following:

1. Excellent Insulation Performance

The tabs (mostly nickel strips for the positive electrode and hydrogen storage alloy current collectors for the negative electrode) of nickel-metal hydride batteries are conductive metals. Therefore, the tape must possess high insulation resistance, effectively isolating the tabs from the battery case, separator, adjacent electrodes, and other components, blocking unintended conductive paths and fundamentally preventing short circuits. This is its most fundamental core function.

2. Alkali Resistance and Electrolyte Corrosion Resistance

The electrolyte within nickel-metal hydride batteries is an alkaline solution (such as potassium hydroxide solution). Due to the long-term exposure of the tape to a strong alkaline environment, it must exhibit extremely strong alkaline resistance—no swelling, dissolution, delamination, or degradation. Furthermore, the adhesive must not be corroded by the electrolyte and fail (e.g., debonding). This ensures structural and performance stability throughout the battery’s lifecycle. 3. Suitable Temperature Resistance

NiMH batteries generate a certain amount of heat during charging and discharging (operating temperatures typically range from -20°C to 60°C, and may be higher in extreme cases). The adhesive tape must maintain stability within this temperature range: the substrate must not become brittle or soften, and the adhesive must not bleed, ensuring a secure bond.

4. Appropriate Adhesion and Conformability

Adhesion requires a balance: it must adhere tightly to the metal or substrate surfaces, such as the tabs and electrode sheets, to prevent peeling during battery assembly (such as winding and lamination) or use; while also avoiding excessive adhesion, which could damage components during processing.

Conformability: It must conform to the tab edges and curves, avoiding bubbles and wrinkles, ensuring complete insulation. In particular, it must cover any burrs on the tabs to prevent them from puncturing the separator.

5. Good Mechanical Strength

It must possess adequate tensile and tear resistance to withstand the mechanical stresses of battery assembly (such as tension during winding). It must also withstand minor friction or impact with the tab edges to prevent insulation failure due to tape damage.

6. Process Compatibility

It must meet the requirements of automated production, such as easy cutting and unwinding (no sticking or excessive tightening), low warping after lamination, and adaptability to the tab dimensions (typically narrow widths of 4-10mm) to ensure production efficiency and consistency.

NiMH battery tape is primarily used for internal insulation and fixation, particularly for protecting the positive tab. It’s typically composed of two main components: a base material and an adhesive.

To quickly understand its main material composition, here’s a summary of common types and characteristics:

Material Components

Common Types

Main Characteristics

Application Notes

Base Material

BOPP (Biaxially Oriented Polypropylene Film)

The most commonly used, thickened material offers low cost, excellent overall performance, and superior electrical insulation. It’s the preferred base material for most NiMH battery tapes.

Adhesive

Alkali-resistant rubber pressure-sensitive adhesive

Designed specifically for the alkaline environment of NiMH batteries, it effectively resists electrolyte corrosion, is acid and alkali resistant, offers moderate adhesion, and exhibits good initial tack.

1. Tab insulation protection

This is its most core function. The positive tab (usually a nickel strip) of a NiMH battery is a conductive metal. The tape must tightly wrap around the tab, isolating it from other components such as the battery casing, negative current collector, and separator. This prevents the tab from contacting conductive components and causing short circuits, thereby fundamentally avoiding performance failure or safety hazards caused by internal short circuits in the battery.

2. Preventing tab burrs from piercing the separator

During the tab processing process, tiny burrs may form. If they come into direct contact with the separator, they may pierce the separator and cause a short circuit between the positive and negative electrodes. Wrapping the tab with tape can cover these burrs, forming a physical barrier, protecting the integrity of the separator, and ensuring the safety of the battery’s internal structure.

3. Securing the tab position

During battery assembly (such as winding and lamination), the tab must remain stable to prevent shifting and contact with other components. Adhesive tape secures the tab to the electrode sheet or designated location with moderate adhesion, preventing loosening or shifting during processing or use, and ensuring the stability of the battery structure.

4. Isolation from Electrolyte Corrosion

NiMH batteries contain an alkaline electrolyte (such as potassium hydroxide solution). The alkaline-resistant material of the adhesive tape (such as the PP backing) reduces direct electrolyte corrosion at the base of the tab or the edge of the electrode sheet, while also protecting the adhesive from electrolyte damage, maintaining a long-term bond.