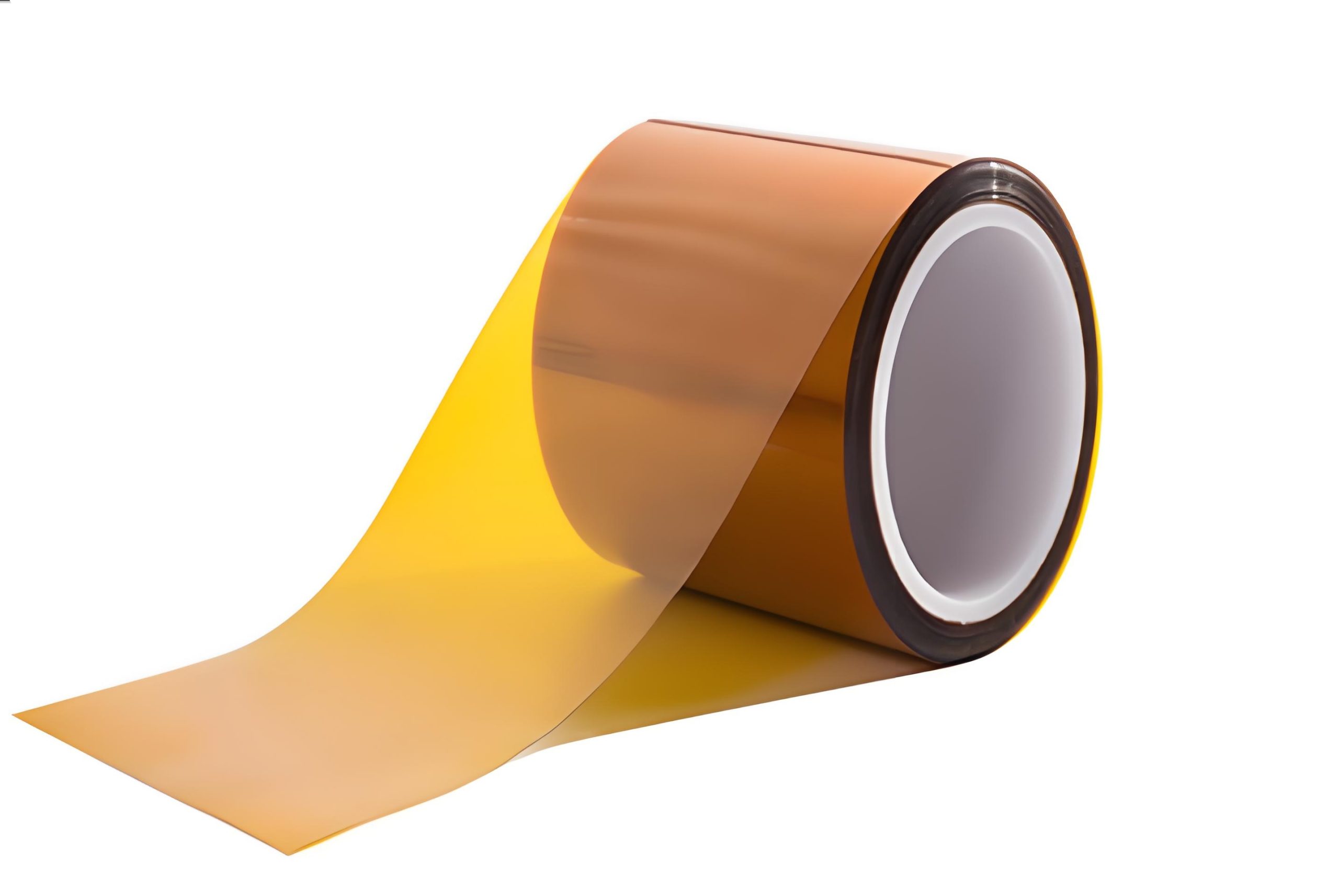

Polyimide double-sided tape

Double-sided polyimide tape is a high-temperature resistant tape made of polyimide film as the base material and coated with high-performance adhesive on both sides. It has excellent temperature resistance (typically -269℃ to 260℃), electrical insulation and chemical stability, and is suitable for scenarios such as fixing electronic components and shielding in high-temperature environments.

Production Process Flow

From raw materials to finished product, every step is rigorously controlled to ensure consistent and reliable performance.

Select PI substrate (25-125μm), suitable adhesives (silicone/acrylic), and release materials. Test key indicators such as thickness, viscosity, and cleanliness, and reject substandard raw materials.

Polyimide double-sided tape Series Specification Sheet

| Name | Item No.Model | Material | Colour | Adhesive | standard size | Adhesion (N/25mm) | Tensile strength (N/25mm) | Temperature resistance °C | |

|---|---|---|---|---|---|---|---|---|---|

| thick/mm | long/m | ||||||||

| Polyimide double-sided tape | DS10K | PI | Golden | Silicone | / | / | 3.5↑ | 170↑ | 250 |

Application Showdown: Double-Sided Polyimagevs. Single-Sided Polyimide Tape

Functions, Uses, and Applications

Black Polyimide Tapes is an indispensable material in electronic manufacturing. Its core function is to ensure reliability and performance of electronic components via excellent thermal resistance, insulation, and adhesion throughout complex production workflows.

Quality Standards & Certifications

Jiujiang Leadcomp Co., Ltd. is committed to delivering the highest quality products, a promise backed by strict internal standards and authoritative third-party certifications.