Polyimide film

Polyimide Film is a high-performance engineering film known for its excellent heat resistance and outstanding dimensional stability. It can withstand prolonged exposure to high temperatures without melting, deforming, or degrading, making it suitable for demanding industrial applications.

Thanks to its strong electrical insulation and chemical resistance, Polyimide Film is widely used in electronics, flexible circuits, 3D printing build surfaces, and as a base material for high-temperature adhesive tapes. Its reliable performance makes it an ideal choice for environments where durability and precision are essential.

Polyimide Film Selling Points

- Excellent High-Temperature Resistance – Polyimide Film performs reliably in extreme heat without melting or deformation

- Outstanding Electrical Insulation – Polyimide Film provides stable insulation for electronic and electrical applications

- Strong Dimensional Stability – Polyimide Film maintains its shape under thermal and mechanical stress

- Chemical and Solvent Resistance – Polyimide Film withstands oils, solvents, and harsh industrial environments

- Thin, Lightweight, and Flexible – Polyimide Film is easy to process, cut, and apply

- Long Service Life – Polyimide Film resists aging and thermal cycling for durable performance

Polyimide film Specification Sheet

| NO | Index Name | Unit | 25μm | 50μm | 75μm | 100μm | Test Method |

|---|---|---|---|---|---|---|---|

| Product Specifications | |||||||

| 1 | Thickness | μm | 25 | 50 | 75 | 100 | |

| 2 | Width | mm | 10-520/1040 (per customer req.) | 10-520/1040 (per customer req.) | 10-520/1040 (per customer req.) | 520 (per customer req.) | |

| 3 | Length | m | 500-3000 (per customer req.) | 500-2000 (per customer req.) | 500-2000 (per customer req.) | 300-800 (per customer req.) | |

| Performance Indicators | |||||||

| 4 | Heat Resistance | ℃ | ≥280 | ≥280 | ≥280 | ≥280 | GB/T 13542.6-2006 |

| 5 | Thickness Tolerance | % | ±10 | ±10 | ±10 | ±10 | GB/T 13542.6-2006 |

| 6 | Tensile Strength | MD (MPa) | ≥160 | ≥160 | ≥150 | ≥145 | GB/T 13542.6-2006 |

| TD (MPa) | ≥140 | ≥140 | ≥130 | ≥120 | |||

| 7 | Elongation at Break (MD, TD) | % | ≥40 | ≥50 | ≥50 | ≥50 | GB/T 13542.6-2006 |

| 8 | Power Frequency Electrical Strength | MV/m | ≥220 | ≥200 | ≥165 | ≥150 | GB/T 13542.6-2006 |

| 9 | Surface Resistivity (200℃) | Ω | ≥1.0×10¹³ | ≥1.0×10¹³ | ≥1.0×10¹³ | ≥1.0×10¹³ | GB/T 13542.6-2006 |

| 10 | Volume Resistivity (200℃) | Ω·m | ≥1.0×10¹⁰ | ≥1.0×10¹⁰ | ≥1.0×10¹⁰ | ≥1.0×10¹⁰ | GB/T 13542.6-2006 |

| 11 | Relative Permittivity (48-62HZ) | —- | 3.5±0.4 | 3.5±0.4 | 3.5±0.4 | 3.5±0.4 | GB/T 13542.6-2006 |

| 12 | Dielectric Loss Factor (48-62HZ) | —- | ≤4.0×10⁻³ | ≤4.0×10⁻³ | ≤4.0×10⁻³ | ≤4.0×10⁻³ | GB/T 13542.6-2006 |

| 13 | Density | g/cm³ | 1.420±0.02 | 1.420±0.02 | 1.420±0.02 | 1.420±0.02 | GB/T 13542.6-2006 |

| 14 | Marginal Laceration | N | Negotiated by Both Parties | Negotiated by Both Parties | Negotiated by Both Parties | Negotiated by Both Parties | GB/T 13542.6-2006 |

| 15 | Color | —- | Tea Color | Tea Color | Tea Color | Tea Color | Visual Inspection |

Customizable styles

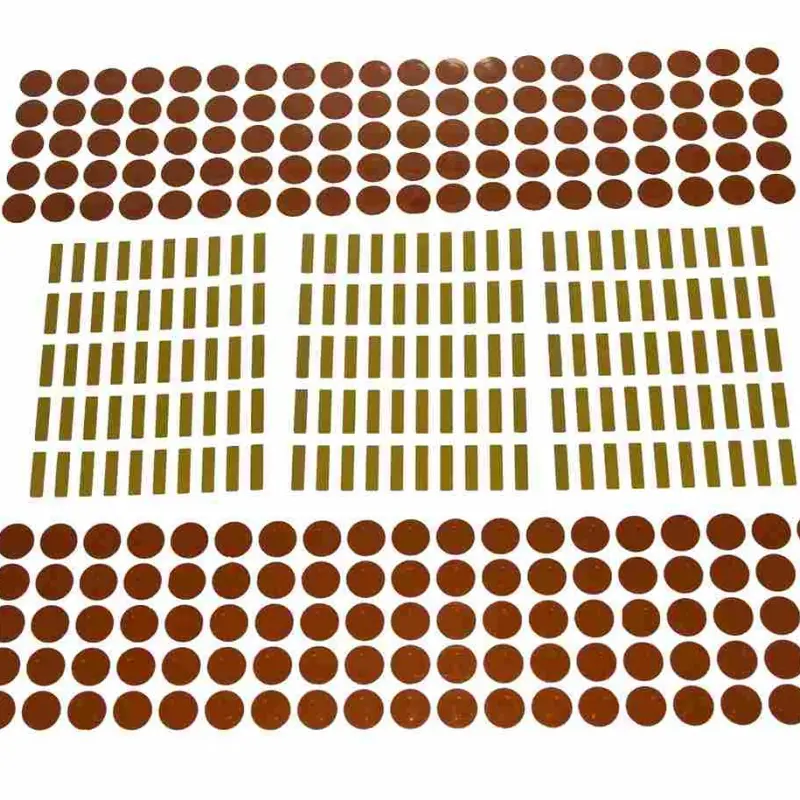

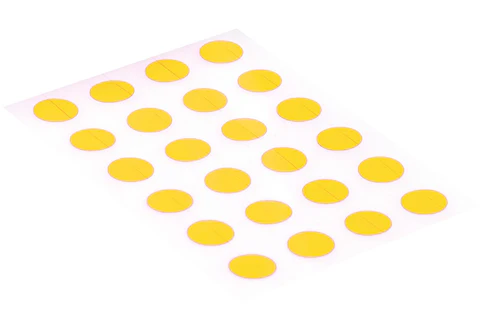

1. Polyimide CIRCLES

Primarily used for localized masking and protection in electronic manufacturing, such as:

- precise masking during PCB wave soldering and gold finger spraying (to prevent solder joints/gold fingers from being contaminated);

- protection of specific areas in high-temperature spraying processes (high temperature resistance, easy peeling, and no residue).

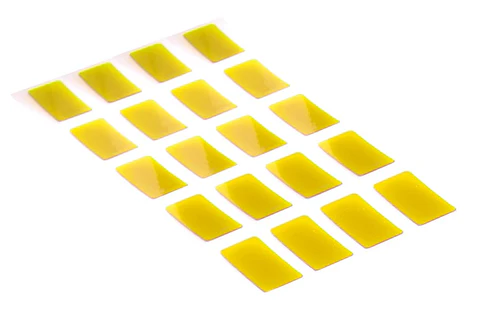

2. Polyimide rectangular

It belongs to the category of die-cut custom shapes and is commonly used for:

- fixing and insulating the positive/negative tabs of lithium batteries;

- component masking in SMT (Surface Mount Technology) processes;

- partial insulation wrapping of motor and transformer coils.

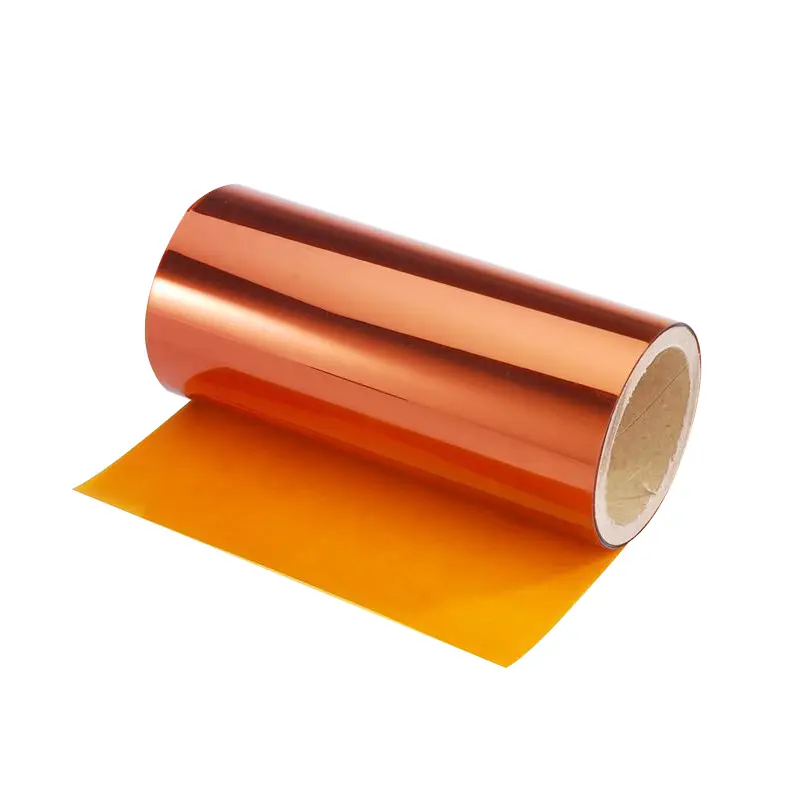

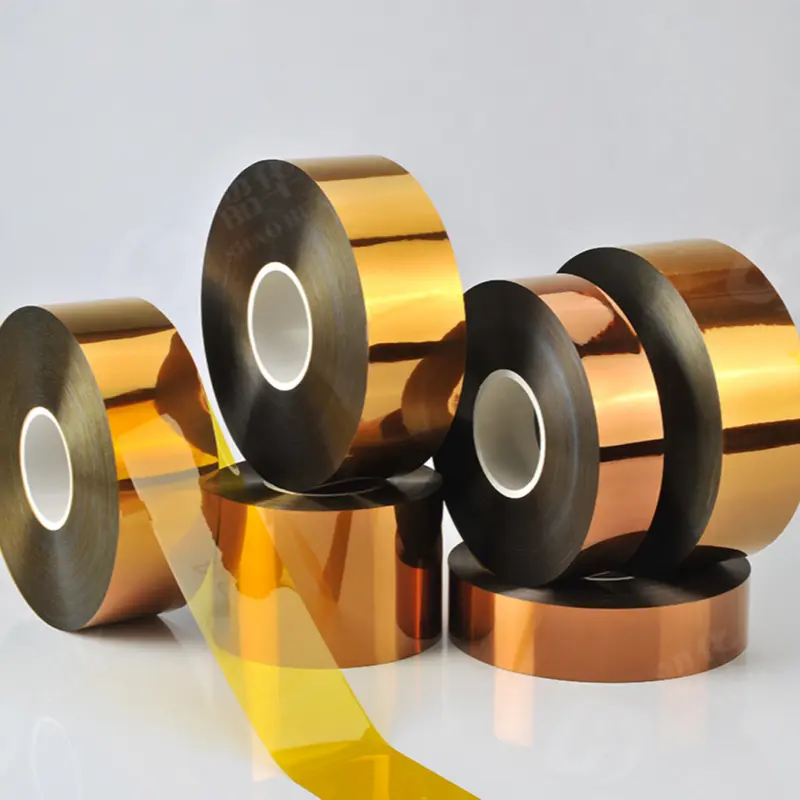

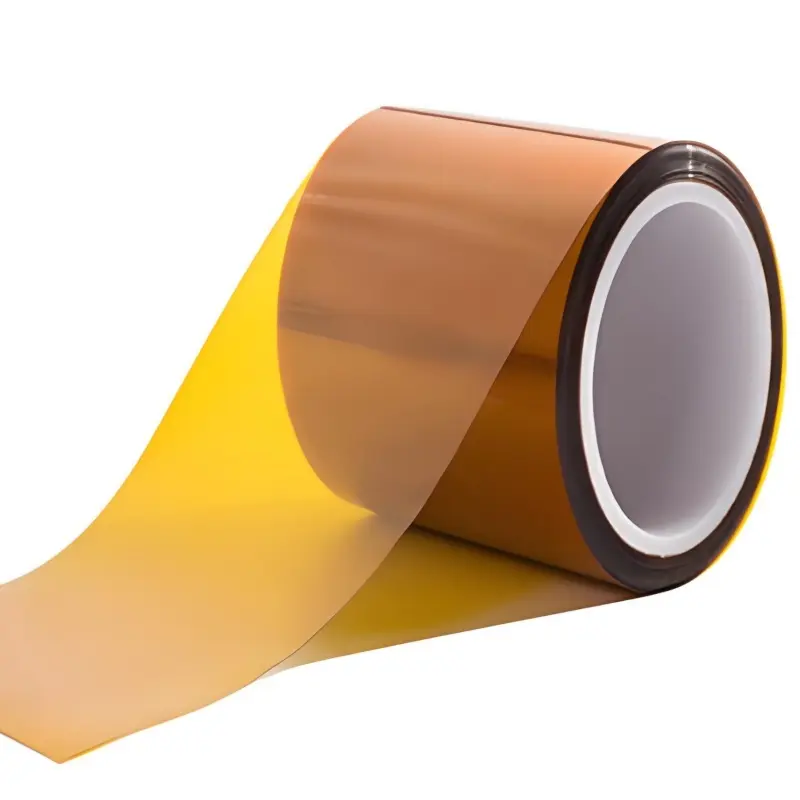

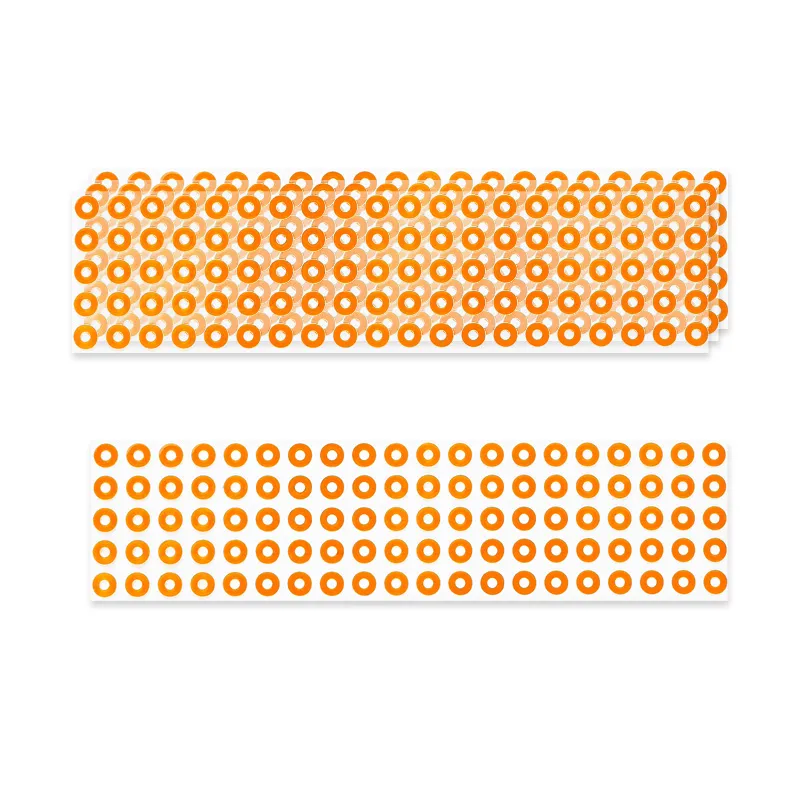

3. Polyimide Rolls

Supplied in roll form, suitable for large-area/continuous processing scenarios:

- Coil insulation wrapping for motors and transformers (resistant to high and low temperatures, high insulation level);

- Substrate for flexible printed circuits (FPC);

- High-temperature insulating sleeves for cables.

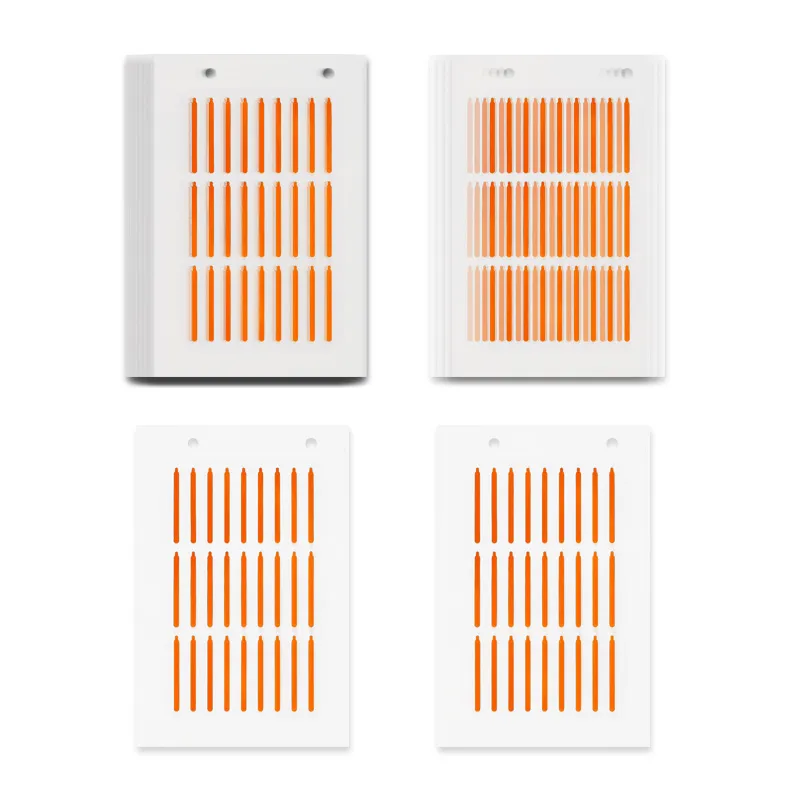

4. Polyimide Sheets

Suitable for large-area/custom-size insulation/substrate needs:

- Encapsulation substrates for high-temperature heating films (such as heating elements in aerospace/medical equipment);

- Sample support films for X-ray fluorescence spectroscopy (XRF) analysis;

- Structural support and overall protection of gold fingers for flexible circuit boards.

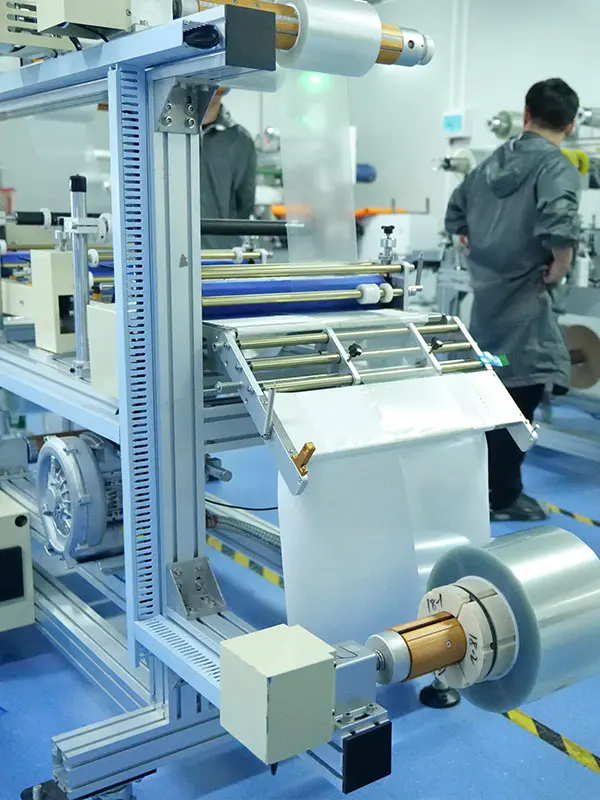

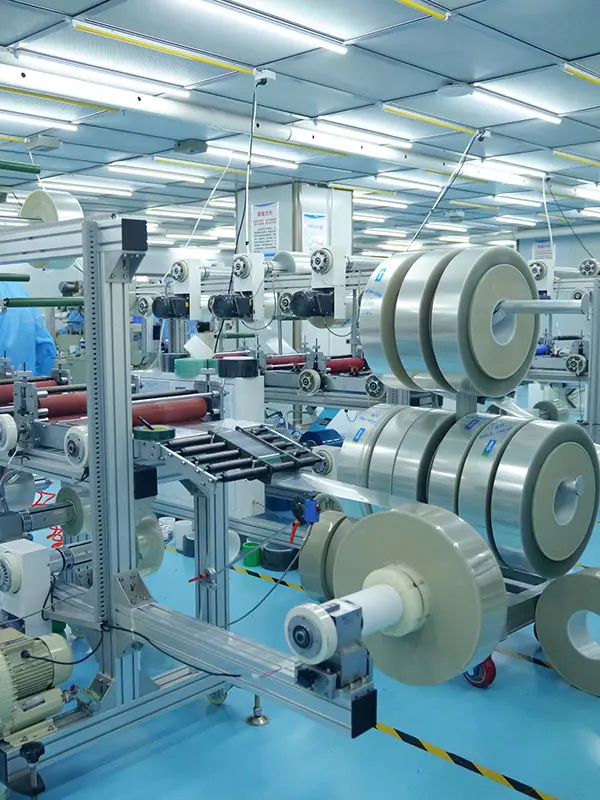

Our Production Equipment

Jiujiang Leadcomp Co., Ltd. has many years of experience in the manufacturing of high-temperature tapes. Our factory is equipped with advanced slitting, die-cutting, and coating equipment, enabling large-scale, precise, and high-quality production. Each roll of tape undergoes rigorous quality control to ensure its reliability and consistency in industrial applications.

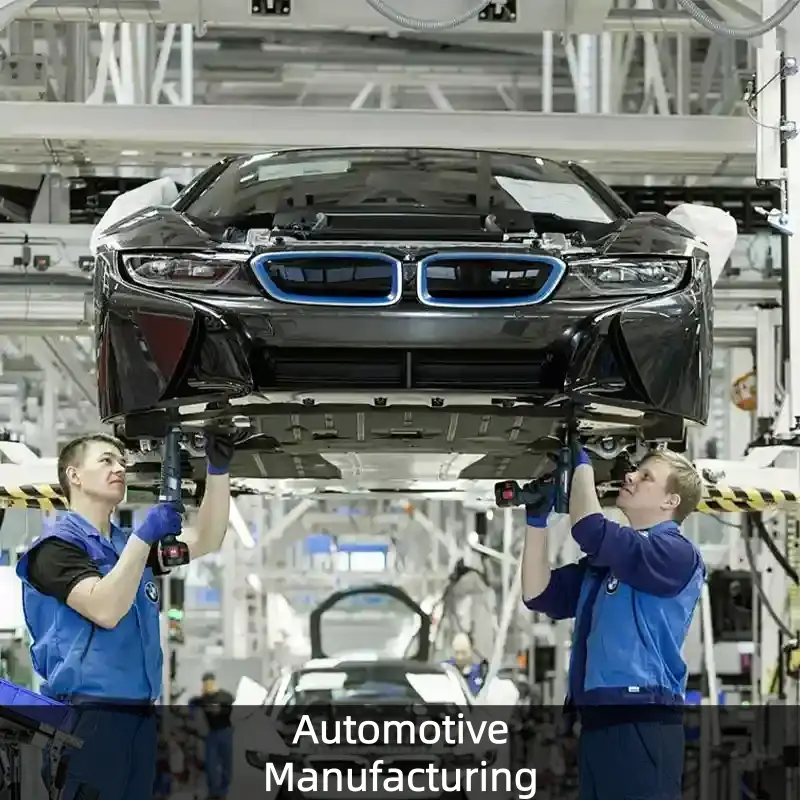

Customer Success Stories

Jiujiang Leadcomp Co., Ltd. provides high-quality ODM and OEM tape solutions for numerous industries, customizing die-cut tape products to meet each customer’s unique needs. With years of experience in precision die-cutting, we pride ourselves on advanced processes and attention to detail. The following showcases our superior die-cutting technology and samples, reflecting our relentless pursuit of quality and precision.