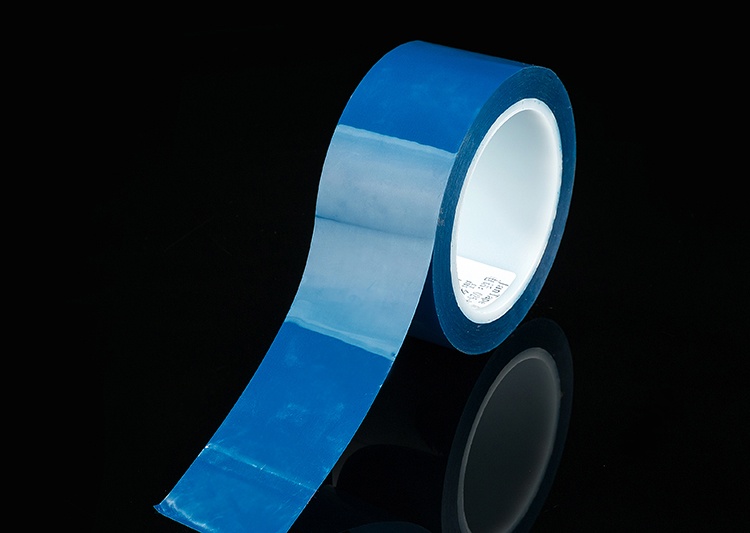

Power battery blue film tape

High-temperature tape for lithium batteries is made of insulating materials (PP, PET, PI films) as the base material, with a special acrylic adhesive resistant to lithium battery electrolytes coated on it. Its thicknesses are 0.016mm, 0.020mm, 0.03mm, 0.035mm, 0.04mm, and 0.05mm.

Features: High temperature resistance, voltage resistance, no deformation, and no warping.

Application: Used for packaging the exterior of power batteries (prismatic aluminum-shell batteries).

Detailed description

The power battery blue film tape uses a double-layer composite PET film as the base material and is coated with high-viscosity acrylic pressure-sensitive adhesive. The adhesive surface is smooth and has no white spots and is flat.

Related Specifications

| Name | ltem No.Model | Material | Colour | Adhesive | standard size | Tack | Adhesion Strength | Tensile Resistance | Exten- sibility | Voltagewithstand | Temperature tolerance | ||

| thick/mm | wide/mm | long/m | N | N/25mm | N/25mm | % | ℃ | ||||||

| Power battery blue film tape | PT11A | PET | blue | acrylic acid | 0.11 | 950 | 50/100 | 3.5↑ | 10↑ | 150↑ | 45 | 5kv | 120 |

| Power battery blue film tape | PT08A | PET | blue | acrylic acid | 0.08 | 950 | 50/100 | 4↑ | 10↑ | 120↑ | 40 | 5kv | 120 |

FAQ

Lens Protection Tape Series

Specialized for encapsulating resin eyeglass lenses during high-temperature curing processes. Key features include high transparency, residue-free removal, and heat resistance up to 130°C (e.g., JT8860 for blue-light-blocking lenses)

Lithium Battery Tape Series

Includes termination tapes (for electrode insulation), PACK tapes (bundle fixation), and tab lead tapes (welding point protection). Made from PI/PET films with electrolytic corrosion resistance, critical for cylindrical/pouch cell safety

LED Encapsulation High-Temperature Tape Series

Designed for LED epoxy resin filling and curing (e.g., MY68C transparent tape for digital tubes). Withstands 150–180°C, prevents overflow, and leaves no residue after peeling

Connector Tapes Series

Insulating tapes for electronic connectors and terminals, ensuring stability in soldering (reflow peak: 260–300°C). Commonly uses PI films for dielectric strength

Insulation & Fixation Tapes Series

Glass fiber-reinforced tapes for coil binding in motors/transformers, offering mechanical strength and flame retardancy (180–220°C continuous use)

High-Temperature Double-Sided Tape Series

Features acrylic/silicone adhesives on PI/PET bases. Used for bonding heat sinks, battery modules, and composite materials, withstanding 120–180°C long-term

Masking Tapes Series

Includes high-temp masking paper and PET green tapes for spray painting, powder coating, and PCB gold finger protection. Resists solvents, leaves sharp edges, and operates at 150–230°C

Teflon Tape Series

PTFE-based tapes with ultra-low friction and 260–300°C continuous resistance. Applied in non-stick industrial conveyors, food packaging seals, and chemical equipment lining

Yes, we can develop tailored solutions based on your sketches or ideas to address your business challenges.

The Company serves all customer segments, offering tailored solutions for large enterprises, small businesses, and individual users.

1. Precise Adhesion Control

Providing stable and moderate adhesion, it securely secures components such as electrodes, separators, and cells (especially preventing shifting during lamination and winding). It also allows for residue-free removal during subsequent processes, preventing adhesive contamination of internal battery materials (such as electrode and electrolyte contact areas), thereby ensuring uncompromising battery performance.

2. Excellent High-Temperature Resistance

It withstands high-temperature processes such as laser welding, baking, and hot pressing in power battery production (typically 120°C to 200°C or even higher) without melting, deformation, or adhesive failure, ensuring process stability.

3. Excellent Insulation

Some blue film tapes exhibit high insulation resistance, effectively isolating conductive components of different polarities within the battery (such as electrode and housing, tab and separator), reducing the risk of short circuits and ensuring compliance with battery safety standards.

4. Strong Dimensional Stability

It is resistant to shrinkage, deformation, or breakage under stretching, temperature fluctuations, or processing stress. It precisely conforms to component dimensions, ensuring accuracy in processes such as electrode alignment and masking, and preventing dimensional deviations from the tape from impacting battery performance.

5. Chemical Resistance

It resists corrosion from electrolytes (such as carbonate solvents), cleaning agents, coolants, and other chemicals encountered during power battery production. It does not swell, degrade, or experience viscosity loss due to chemical reactions, ensuring functional stability in complex chemical environments.

These core properties collectively ensure that power battery blue film tape secures, protects, insulates, and shields key components during the production process, making it a crucial auxiliary material for improving battery production quality and safety.

1. Common Backing Materials

Polyester Film (PET Film)

One of the most widely used backing materials. PET film offers excellent high-temperature resistance (can withstand temperatures of 120-200°C), dimensional stability (not prone to stretching or shrinking), insulation, and chemical resistance, making it suitable for applications such as laser welding, baking, and electrolyte contact in battery production. The blue color is typically achieved by coating the PET film with a blue dye or through co-extrusion, providing both light-blocking and marking functions.

2. Common Pressure-Sensitive Adhesive Layers

The pressure-sensitive adhesive (PSA) is key to the tape’s adhesion, temperature resistance, and residue-free properties. Common types include:

Acrylic PSA

This is the most widely used, offering excellent high-temperature resistance (matching the temperature range of the PET backing material), chemical resistance (resistance to electrolytes and cleaning agents), stable adhesion, and minimal adhesive residue when peeled, meeting the cleanliness requirements of power batteries.

Power battery blue film tape uses PET film + acrylic adhesive as the most mainstream combination, taking into account performance, cost and process adaptability.

The company primarily provides the following types of power battery blue film tape: PT11A, PT08A.