Why Black Polyester Tape Is Becoming a Preferred Choice in Electronics & Automotive Manufacturing

In the high-stakes world of modern manufacturing—where miniaturization, thermal management, and long-term reliability are paramount—every component choice is critical. One surprisingly versatile hero material that has quietly become indispensable is black polyester (PET) film tape.

Far more than simple adhesive, this material offers a unique combination of mechanical, thermal, and electrical properties, coupled with key aesthetic advantages, making it the preferred solution for securing, insulating, and protecting critical assemblies in both electronics and automotive production lines.

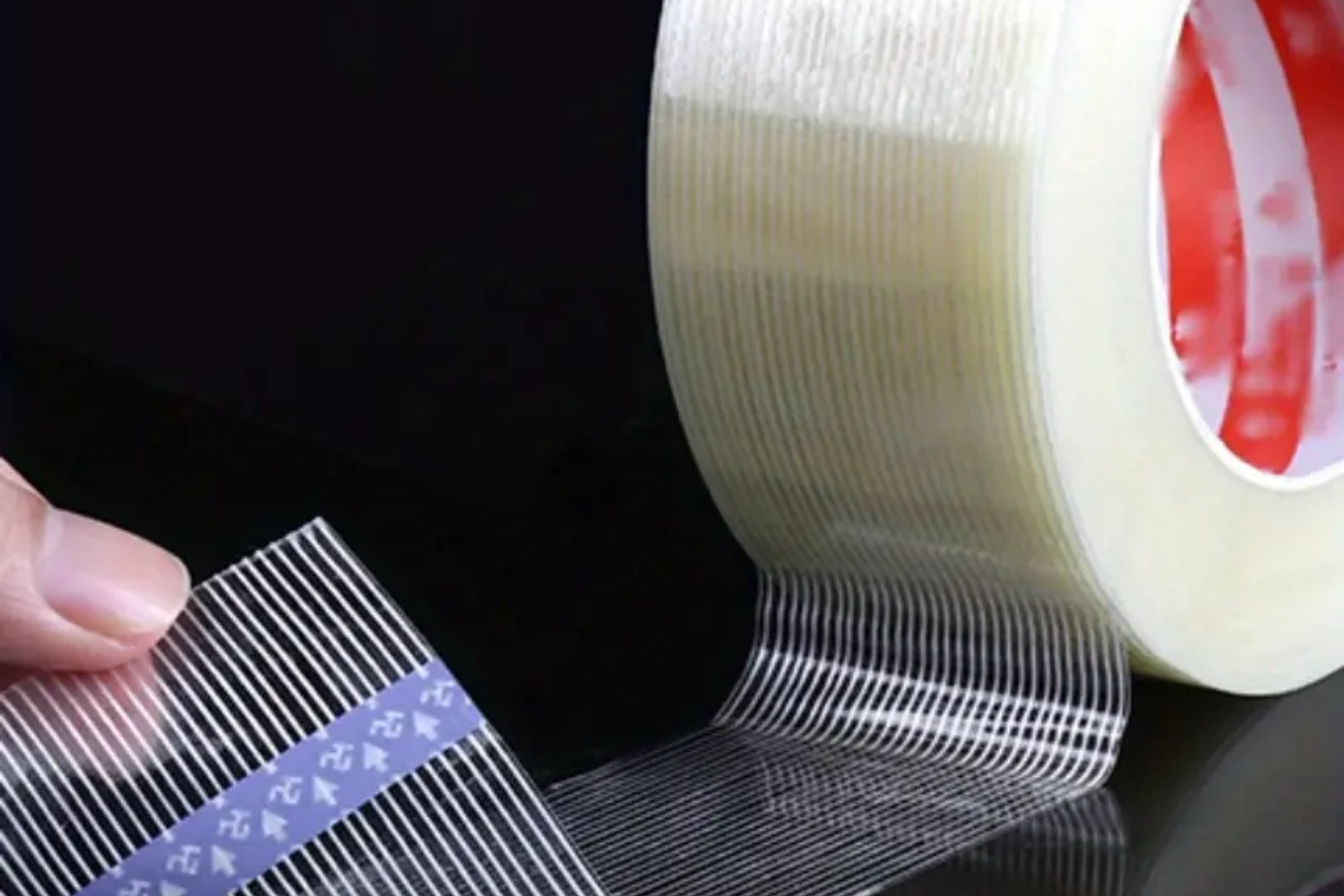

The Core Advantages of Polyester (PET) Film

Black polyester tape starts with the fundamental strengths of polyethylene terephthalate (PET), a robust polymer film. Its popularity stems from its ability to maintain stable performance under extreme and continuous operating conditions.

Comparative Data: Tape Performance

To understand the advantages of polyester tape, it’s best to compare it with other common industrial tapes. Use the chart below to see how various materials perform on key metrics. This highlights why PET tape is often the most well-rounded choice.

Max Temperature

Abrasion Resistance

Conformability

Relative Cost

Application in Electronics Manufacturing

Masking and Protection During Soldering

The tape’s high-temperature resistance and clean removal (especially when paired with silicone or high-performance acrylic adhesives) make it the ideal masking material for printed circuit boards (PCBs). It protects gold contacts, sensitive components, and connectors from solder flux, excessive heat, and cleaning solvents during assembly, ensuring that once removed, it leaves no adhesive residue that could compromise the circuit’s performance.

Component Securing and Insulation

As devices shrink, battery packs, flexible printed circuits (FPCs), and sensitive internal wiring must be securely held without adding unnecessary bulk. Black PET tape provides a strong, thin, and non-conductive anchoring solution, perfect for dual insulation and fixation in confined spaces.

Application in Automotive Manufacturing

The automotive industry demands materials that can endure constant vibration, temperature extremes, and long-term aging—conditions where standard tapes would quickly fail.

Wire Harness Bundling and Protection

Modern vehicles contain kilometers of wiring, grouped into harnesses. Black polyester tape is widely used for bundling these harnesses, providing superior abrasion resistance to protect the wires from friction caused by vibration against surrounding metal components. Its robust backing ensures the harness remains intact and protected for the vehicle’s lifespan.

Interior and Exterior Aesthetic Blackout

Black tape is increasingly adopted as a “blackout” solution. Automotive manufacturers use specialized matte or glossy black PET tapes as a cost-effective, durable, and production-friendly alternative to painting intricate parts. This includes masking the seams of door pillars, window sashes, and interior dashboard trim to create a cohesive, high-end appearance that resists UV degradation and weathering.

The Significance of the Color: Why Black?

While polyester tape is available in many colors (such as green for masking), black offers distinct functional and aesthetic advantages that solidify its position as the preferred choice for permanent applications.

Black polyester film tape’s ascent to a preferred component in electronics and automotive manufacturing is no accident. It is a powerful example of material engineering meeting demanding industrial requirements. By combining high dielectric strength, remarkable thermal stability, and mechanical toughness with the crucial aesthetic and UV resistance provided by its color, PET tape delivers a reliable, efficient, and durable solution for securing, insulating, and protecting the core systems of the products we rely on daily.