Why Kapton Polyimide Is Essential

In a world of shrinking devices and rising power demands, this “super engineering plastic” is the foundational requirement for survival under stress.

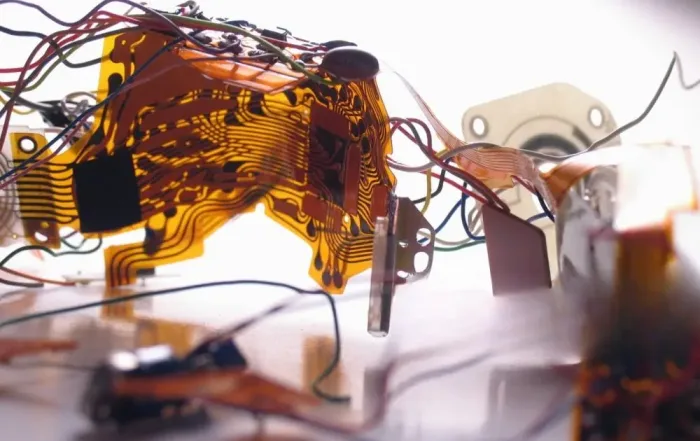

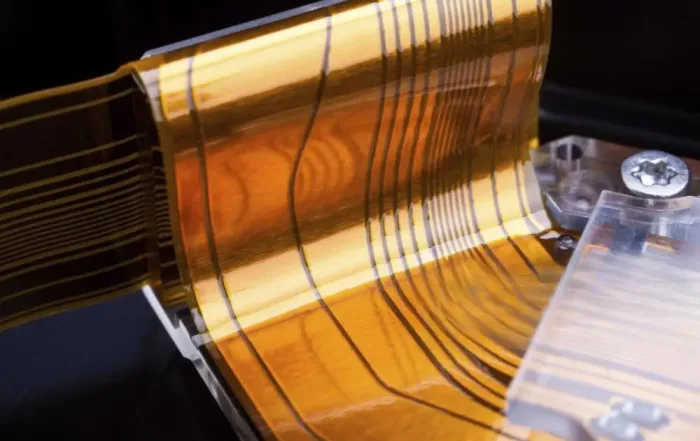

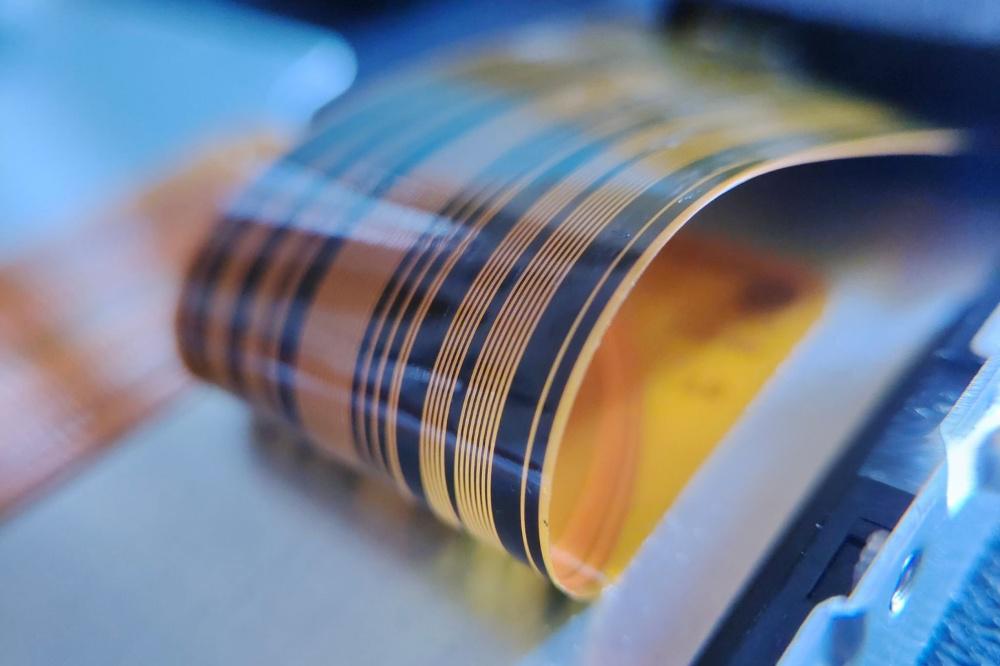

Often referred to as a “super engineering plastic,” polyimide film is not just a material choice—it is a foundational requirement for manufacturing circuits and components that must perform reliably under thermal, electrical, and chemical duress. Its essential status in high-reliability electronics stems from a unique confluence of mechanical, thermal, and electrical properties that few other materials can match.

01 The Thermal Wall

02 Unrivaled Insulation

High-reliability applications demand zero tolerance for electrical failure. Polyimide is inherently an outstanding electrical insulator, making it a crucial component for preventing shorts.

Also used in Coils & Motors: In demanding industrial applications, it wraps wire harnesses and insulates motor windings to prevent arcing in heat-saturated environments.

03 Manufacturing Integrity

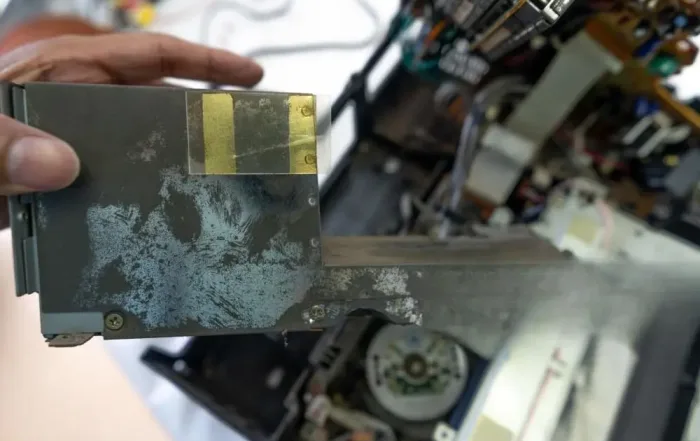

Kapton’s most visible role in the electronics assembly line is as a high-temperature masking material.

04 The Backbone of Durability

“High-reliability” is synonymous with durability, performance under stress, and long-term functional stability. By combining extreme thermal resilience, industry-leading electrical insulation, and unparalleled dimensional stability, Kapton films allow electronics engineers to push the boundaries of miniaturization.

Share This Article

Latest Articles

What Is Polyimide Tape Used For in Industrial and Technical Applications

What Is Polyimide Tape Used For in Industrial and Technical Applications [...]

Kapton Tape Explained: Composition, Applications, and Temperature Resistance

Kapton Tape Explained: Composition, Applications, and Temperature Resistance Kapton tape is a high-performance adhesive [...]

Polyimide Tape for 3D Printing Achieving Strong and Stable Bed Adhesion

Polyimide Tape for 3D Printing Achieving Strong and Stable Bed Adhesion Why Polyimide [...]